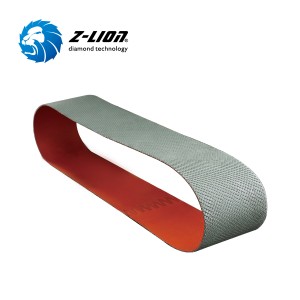

Z-LION Glass Edge Grinding and Seaming Diamond Grinding Belt for Automatic Glass Processing Machines

Z-LION Glass edge grinding and seaming diamond belts are designed to be used on automatic glass processing machines such as LiSEC KSR & KSV vertical automatic arrissing machines, Ashton Industrial SeamMaXX SOLO Plus automatic seaming line, GLASSLINE automated belt seaming line, etc. or on stand-alone manual cross belt machines for grinding, seaming, arrissing edge of glass panes.

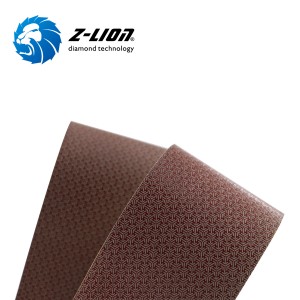

Working surface of Z-LION Glass edge grinding and seaming diamond sanding belts is electroplated flexible diamond sheet which has the following advantages:

• High cut rates because of 100% diamond exposure.

• Long lasting because each individual diamond is held in place by electroplating technology.

• As soft as traditional abrasive sandpaper but lasts much longer.

• Precise diamond placement for best swarf removal and heat dissipation.

• Can be used both wet and dry.

Besides above advantages of electroplated diamond flexible sheets, Z-LION Glass edge grinding and seaming diamond grinding belt also have the following features:

• Provide a lower-cost alternative to diamond wheel seaming, as well as allowing for seaming of various thicknesses without a tooling change.

• Diamond belt is a combination of durability and flexibility, ideal for glass seaming that requires both fine sanding and heavy stock removal.

• Designed to resist thermal and chemical deterioration, which can misshape glass edge during high speed grinding.

• Special pattern design to create bright and consistent finishes on glass edge.

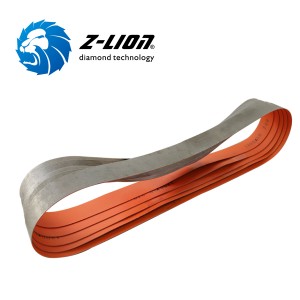

• Quality backing adds accuracy and strength to the belt, dovetail joint is less likely to break.

• Simplicity and ease of operation, reduces downtime and increases yields.

Popular sizes are 1180x80mm, 3350x100mm, 1800x50mm, etc. But can be supplied in any required dimensions.

Popular grits 120# 200# (other grits can be made as per request)

Surface patterns: snowflake, plum blossom, dot, etc.

| Product Name: | Glass edge grinding and seaming diamond belts |

| Item No.: | ZL-123EB |

| Brand: | Z-LION |

| Working surface: | Electroplated flexible diamond sheet |

| Advantages of working surface: | • High cut rates because of 100% diamond exposure. • Long lasting because each individual diamond is held in place by electroplating technology. • As soft as traditional abrasive sandpaper but lasts much longer. • Precise diamond placement for best swarf removal and heat dissipation. • Can be used both wet and dry. |

| Features of the product: | • Provide a lower-cost alternative to diamond wheel seaming, as well as allowing for seaming of various thicknesses without a tooling change. • Diamond belt is a combination of durability and flexibility, ideal for glass seaming that requires both fine sanding and heavy stock removal. • Designed to resist thermal and chemical deterioration, which can misshape glass edge during high speed grinding. • Special pattern design to create bright and consistent finishes on glass edge. • Quality backing adds accuracy and strength to the belt, dovetail joint is less likely to break. • Simplicity and ease of operation, reduces downtime and increases yields. |

| Popular size: | 1180x80mm, 3350x100mm, 1800x50mm |

| Popular grits: | 120# 200# |

| Available grits: | 30# 60# 120# 200# 400# 600# 1000# 2000# 3000# |

| Usage: | Wet grinding |

| Applied machine: | automatic glass processing machines such as LiSEC KSR & KSV vertical automatic arrissing machines, Ashton Industrial SeamMaXX SOLO Plus automatic seaming line, GLASSLINE automated belt seaming line, etc. or on stand-alone manual cross belt machines. |