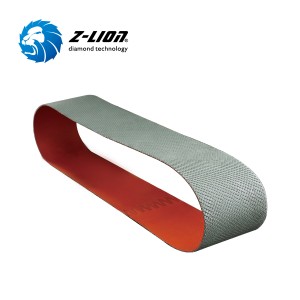

Z-LION Diamond abrasive belts for stone grinding and polishing Masonry grinding belts

Z-LION Electroplated diamond abrasive belts are widely used on portable air belt sanders such as 3M File Belt Sander, Makita 9031 Belt Sander, for grinding and polishing of straight, bevel and round stone edge, inside and outside radius of masonry products, countertop sink cutouts, etc. Works great for granite, marble, silestone, dekton, concrete, terrazzo, tile and other stone and construction materials.

Working surface of Z-LION Masonry diamond sanding belts is electroplated flexible diamond sheet which has the following advantages:

• High cut rates because of 100% diamond exposure.

• Long lasting because each individual diamond is held in place by electroplating technology.

• As soft as traditional abrasive sandpaper but lasts much longer.

• Precise diamond placement for best swarf removal and heat dissipation.

• Can be used both wet and dry.

Besides above advantages of electroplated flexible diamond sheet working surface, Z-LION stone grinding belts also have the following features:

• Very flexible so as to respond well to contours, be able to grind and polish inside and outside radius and other hard to reach areas.

• Open dot pattern with arranged diamonds reduces loading, consistent space provides better channeling for swarf.

• The diamond doesn't break down like conventional sandpaper belts which ensures smooth polishing as well as long lasting.

• Quality backing adds accuracy and strength to the belt, dovetail joint is less likely to break.

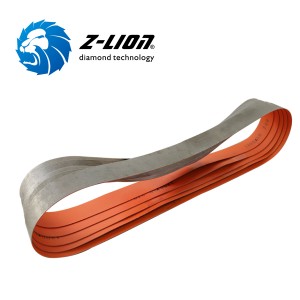

• Ease-of-use, can be in different sizes and fixed to different belt sanders for a wide variety of applications.

Popular sizes are 330x10mm, 520x20mm, 533x30mm, but can be supplied in any required dimensions.

Popular grits 60# 120# 200# 400# (other grits can be made as per request)

Available in open or closed loop.

Available surface patterns: square, hexagon and dot (other patterns can be made as per request)

| Product Name: | Diamond abrasive belts for masonry polishing |

| Item No.: | ZL-123EB |

| Brand: | Z-LION |

| Working surface: | Electroplated flexible diamond sheet |

| Advantages of working surface: | • High cut rates because of 100% diamond exposure. • Long lasting because each individual diamond is held in place by electroplating technology. • As soft as traditional abrasive sandpaper but lasts much longer. • Precise diamond placement for best swarf removal and heat dissipation. • Can be used both wet and dry. |

| Features of the product: | • Very flexible so as to respond well to contours, be able to grind and polish inside and outside radius and other hard to reach areas. • Open dot pattern with arranged diamonds reduces loading, consistent space provides better channeling for swarf. • The diamond doesn't break down like conventional sandpaper belts which ensures smooth polishing as well as long lasting. • Quality backing adds accuracy and strength to the belt, dovetail joint is less likely to break. • Ease-of-use, can be in different sizes and fixed to different belt sanders for a wide variety of applications. |

| Popular sizes: | 330x10mm, 520x20mm, 533x30mm, etc. |

| Other sizes: | Can be custom made |

| Popular grits: | 60# 120# 200# 400# |

| Available grits: | 30# 60# 120# 200# 400# 600# 1000# 2000# 3000# |

| Usage: | Wet and dry |

| Applied machine: | Portable air belt sanders |

| Applications: | Grinding and polishing of straight, bevel and round stone edge, inside and outside radius of masonry products, countertop sink cutouts, etc. |