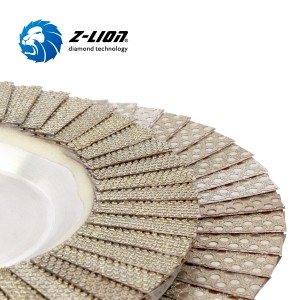

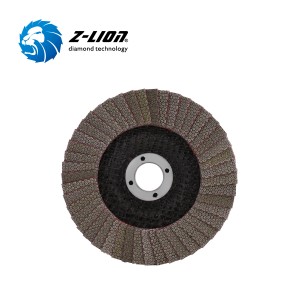

Z-LION Aluminum base diamond flap wheels Diamond flap sanding discs

Z-LION Aluminum base diamond flap disc are designed for fast material removal and deburring on all the hard, brittle materials. In the industry of stone and construction, diamond flap disc are widely used for edge grinding and chamfering as well as surface grinding on granite, marble, silestone, dekton, concrete, terrazzo, tile, etc. Comes with semirigid flaps in mesh pattern and aluminum base with 5/8"-11 or M14 thread.

Features of Z-LION Aluminum base diamond flap wheels are as follows:

• Aluminum base with 5/8"-11 or M14 thread to fit any machine with threaded spindle.

• Electroplated diamond flaps with 100% diamond exposure giving the flap disc fast cutting speed.

• Semirigid diamond flaps are harder than flexible flaps, provide higher stock removal rate as well as longer tool life.

• Special structure design with diamond flaps overlapped sequenced along the rim of the base dissipates heat quickly to avoid flap loosing.

• The overlapped diamond flaps resharpen the flap wheel continuously, ensures aggressiveness and longevity of the flap wheel giving nice and clean finish continuously.

• Diamond flap wheels offer smooth and even grind, reduce hand and arm vibrations of the operator significantly compared to cup wheels.

Popular sizes are 4", 4.5" and 5".

Popular grits are 60# 120# 200# 400# (600# 800# 1500# 3000# can be made as per request.)

Comes with semirigid flaps in mesh pattern.

Comes with aluminum base with 5/8"-11 or M14 thread.

| Product Name: | Aluminum base diamond flap wheels |

| Item No.: | ZL-WMCY02 |

| Brand: | Z-LION |

| Working surface: | Electroplated semirigid diamond sheet |

| Features of the product: | • Aluminum base with 5/8"-11 or M14 thread to fit any machine with threaded spindle. • Electroplated diamond flaps with 100% diamond exposure giving the flap disc fast cutting speed. • Semirigid diamond flaps are harder than flexible flaps, provide higher stock removal rate as well as longer tool life. • Special structure design with diamond flaps overlapped sequenced along the rim of the base dissipates heat quickly to avoid flap loosing. • The overlapped diamond flaps resharpen the flap wheel continuously, ensures aggressiveness and longevity of the flap wheel giving nice and clean finish continuously. • Diamond flap wheels offer smooth and even grind, reduce hand and arm vibrations of the operator significantly compared to cup wheels. |

| Popular sizes: | 4",4.5", 5" |

| Popular grits: | 60# 120# 200# 400# |

| Available grits: | 60# 120# 200# 400# 600# 1000# 2000# 3000# |

| Flaps: | Semirigid flaps in mesh pattern |

| Base: | Aluminum base with 5/8"-11 or M14 thread |

| Usage: | Wet and dry |

| Applied machine: | Angle grinders |

| Applications: | For edge grinding and chamfering as well as surface grinding on granite, marble, silestone, dekton, concrete, terrazzo, tile, etc. |