-

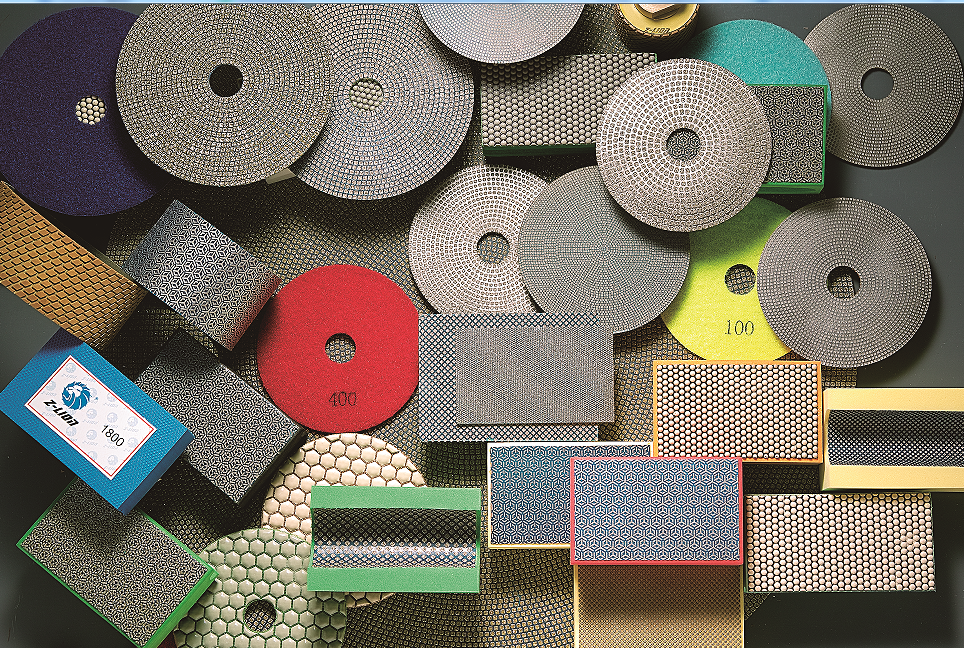

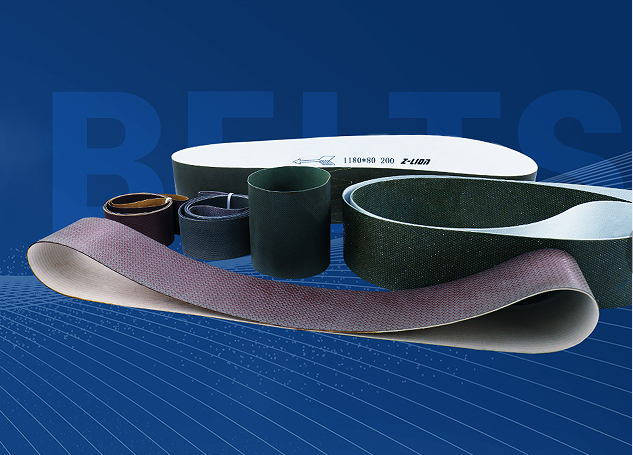

Diamond abrasive belts and diamond flap discs both belong to the classification of abrasive tools, abrasive belt is more flexible than other abrasive tools and more adaptable to the working environment. Although the abrasive belt and the flap discs are both abrasive tools, they have their own adv...Read more »

-

Diamond flap discs are designed to be mounted on hand-held power tools and are used in a variety of applications including weld grinding and polishing, burring, chamfering, surface dusting, and surface polishing of metallic and non-metallic parts. With their unique features and numerous advantage...Read more »

-

Binding agent Let’s delve into the two main combinations of diamond sanding belts and their unique qualities. The first combination is an electroplated bonded diamond sanding belt with a single layer of diamond abrasive. Known for its exceptional sharpness and superior abrasive control, this type...Read more »

-

Electroplated diamond tools offer greater precision and quality. Electroplated diamond tools are changing the way manufacturers handle hard, brittle, and difficult-to-machine materials. From carbide to optical glass, from ceramics to gemstones, electroplated diamond tools offer levels of precisio...Read more »

-

In the industrial world, diamonds are not only a symbol of wealth and luxury but also a key component in the manufacture of cutting and grinding tools. Now, thanks to the electroplating process, it is easier and more efficient to apply this precious substance to the tool substrate. Diamonds are k...Read more »

-

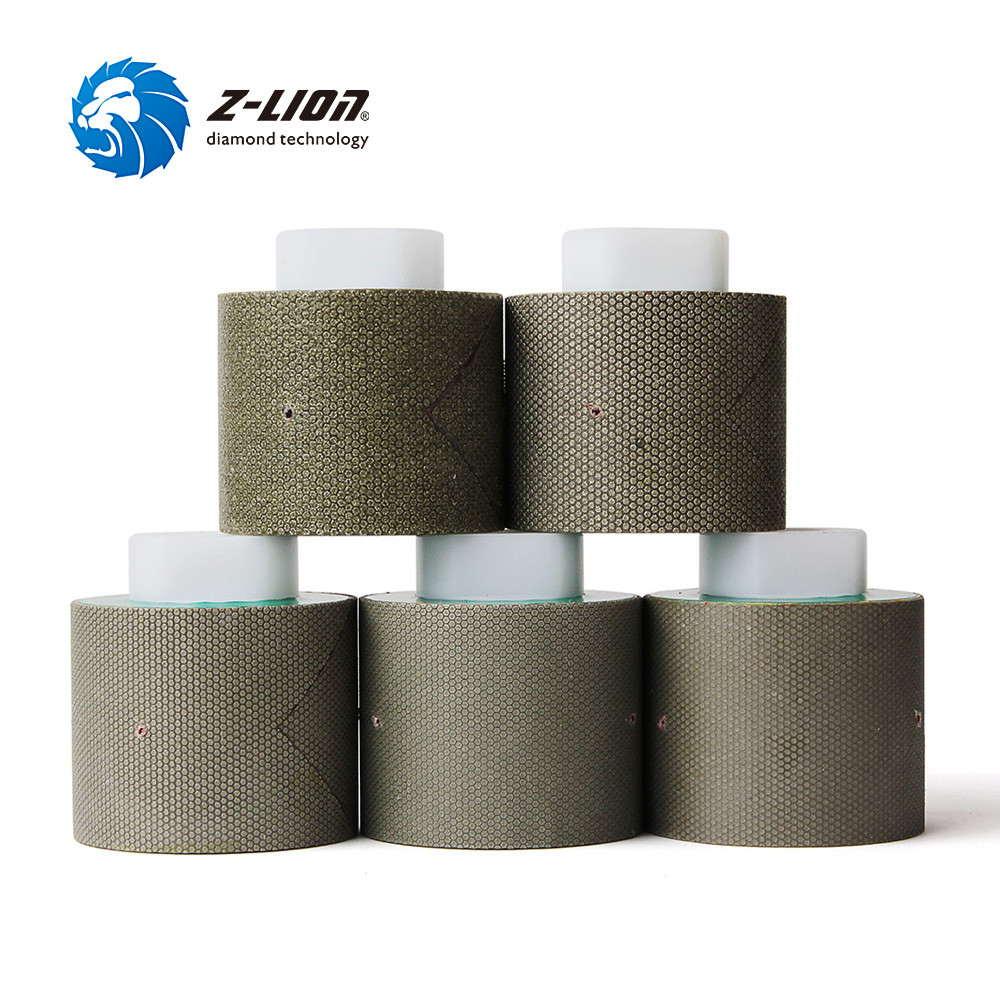

1. High hardness The main advantage of electroplated grinding wheels is their high hardness. This is because the electroplated metal bond used to make this wheel is usually made of nickel or a nickel-cobalt alloy. This binder has a dense structure that enhances the bond and overall hardness. Elec...Read more »

-

The three main parts of an abrasive tool—the base material, the abrasive, and the bond—work together to produce the desired grinding results. The substrate plays a vital role in giving the sanding belt its flexibility. As a carrier for abrasives and adhesives, it is available in various types suc...Read more »

-

Glass is available everywhere, from window panes to cookware to decorative ornaments, it is a permanent fixture all around us. The rough edges of glass have to be sanded down for the piece to be useful. In order to sand glass, you’ll need an abrasive capable of cutting and scratching a glass surf...Read more »

-

Diamond sandpaper is a cutting tool with excellent grinding and wear resistance due to its unique physical and chemical properties. Diamond is a inorganic compound substance, which is naturally produced in kimberlite. Its hardness is up to 10, and it is one of the hardest substances in the world ...Read more »

-

Electroplated diamond polishing pads are an efficient grinding tool suitable for polishing metal rust and other material surfaces. The polishing effect is mainly determined by factors such as the particle size, density, and hardness of the grinding disc. The following are methods for polishing me...Read more »

-

Diamond flap discs are becoming more and more popular in the industry of stone and construction. They are commonly used on hand-held electric or pneumatic angle grinders for sanding, grinding, shaping and smoothing of natural stone, ceramic, porcelain stoneware, concrete, glass etc. Because of t...Read more »

-

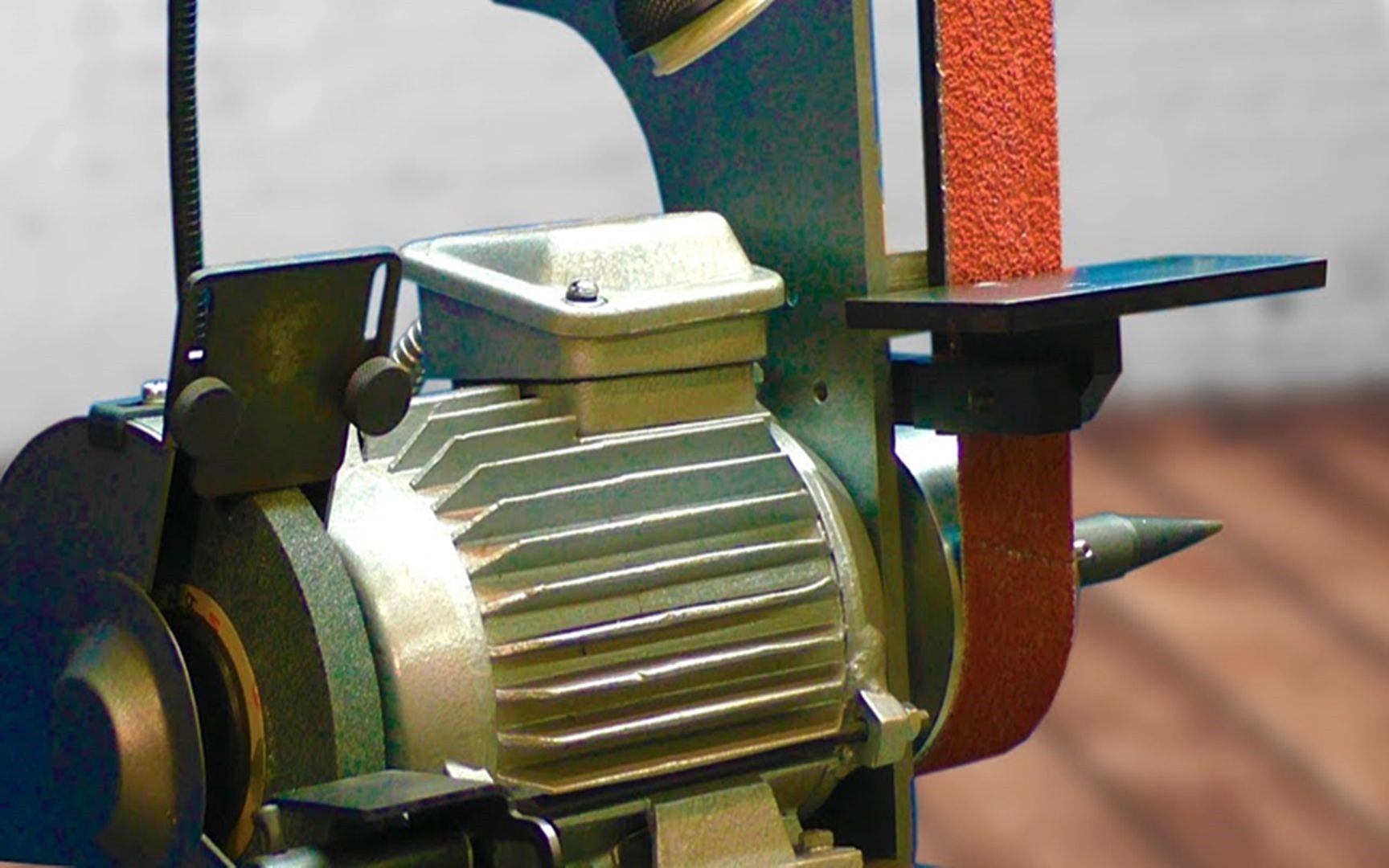

diamond abrasive belt grinding is the process of processing the workpiece by using diamond abrasive belts as abrasive tool, supplemented by contact wheel (or grinding plate), tensioning wheel, driving wheel and other grinding head main parts, as well as tensioning quick-change mechanism, deflecti...Read more »