When sanding concrete, choosing the right concrete sandpaper is essential to achieving a smooth, polished surface. The size and grit of the sandpaper plays a major role in the effectiveness of the sanding process. Here is a detailed guide on how to choose the right sandpaper for sanding concrete.

What Grit Sandpaper for Concrete?

The grit of sandpaper directly affects the polishing effect of the concrete surface. For concrete grinding, it is generally recommended to use sandpaper with a grit range of 60 to 100. Here are the reasons why this range is ideal:

Grit 60 to 80: Sandpaper in this grit range is coarse enough to effectively remove rough particles and imperfections from the concrete surface. It is suitable for the initial grinding stage, with the goal of removing larger imperfections and preparing for finer polishing.

80 to 100 grit: As the sanding process progresses, use sandpaper with a grit of 80 to 100 to create a smoother surface. This grit range is effective in refining the surface and removing any scratches left by the coarse grit, resulting in a smoother appearance.

Using sandpaper in this grit range ensures effective removal of coarse particles without excessive abrasion of the concrete surface. It strikes a balance between efficient material removal and maintaining the integrity of the concrete.

The Importance of Sandpaper Quality

1. Durability and wear resistance: High-quality sandpaper is designed to withstand the rigors of concrete sanding. It is made of durable material that resists wear and tear and can be used for a long time without losing effectiveness. This durability is crucial when working on hard surfaces like concrete, as poorer quality sandpaper can deteriorate quickly, leading to inconsistent results.

2. Uniform distribution of sand particles: The performance of sandpaper is largely affected by the uniformity of its abrasive particles. High-quality sandpaper has an even distribution of grit, ensuring consistent contact with the concrete surface. This uniformity helps achieve more consistent polishing performance, reducing the potential for scratches or uneven surfaces.

3. Effective material removal: Premium sandpaper is designed to effectively remove material from concrete surfaces. It strikes a balance between being rough enough to remove rough spots and fine enough to produce a smooth surface. This effectiveness is crucial to achieving the desired level of polish without much effort.

Characteristics of high-quality sandpaper

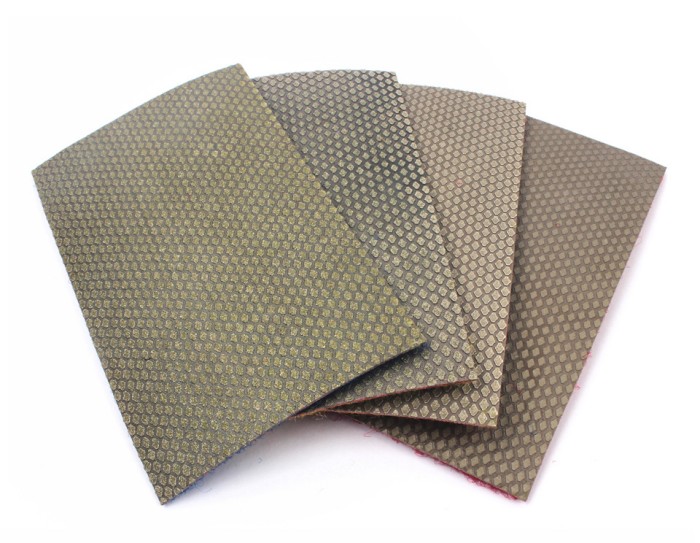

Abrasive: The type of abrasive used in sandpaper affects its performance. Aluminum oxide and silicon carbide are common abrasives used in concrete grinding, but diamond sandpaper goes a step further. Diamond particles are extremely hard and have excellent cutting abilities, making diamond sandpaper an excellent choice for grinding concrete.

Backing material: The backing of the sandpaper should be strong and flexible enough to conform to the surface being worked on. High-quality sandpaper usually has a strong backing material that can withstand the pressure of grinding and maintain its shape.

Binder quality: The binder used to bond the abrasive particles to the backing is also important. The strong adhesive ensures the grain remains intact during use, preventing premature wear and maintaining the effectiveness of the sandpaper.

Why diamond sandpaper is a good choice?

Diamond sandpaper is particularly suitable for sanding concrete due to its unique properties:

1. Super hardness: Diamond is the hardest material known, so diamond sandpaper works extremely well when cutting hard concrete surfaces. This hardness results in faster material removal and a smoother surface.

2. Lifetime: The service life of diamond sandpaper is much longer than traditional sandpaper. While standard sandpaper may wear out quickly, diamond sandpaper retains its cutting ability for a long time, reducing the need for frequent replacement.

3. Wide range of uses: Diamond sandpaper can be used for a variety of grinding tasks, from initial rough grinding to fine polishing. This versatility makes it a valuable tool for professionals and DIY enthusiasts alike.

The Impact of Use Environment on Sandpaper Selection

1. Moisture and moisture resistance

One of the most critical environmental factors to consider is humidity. In humid environments, moisture can affect the performance and life of your sandpaper. Here’s why:

Moisture resistant: Sandpaper designed for use in wet environments usually has a moisture-resistant backing and adhesive. This helps prevent the sandpaper from deteriorating or losing its abrasive properties when exposed to moisture. Using moisture-resistant sandpaper ensures that it retains its effectiveness and durability, even in harsh conditions.

Avoid mold: In high humidity environments, standard sandpaper may be prone to mold, compromising its integrity. Choosing sandpaper designed for wet environments can reduce this risk and ensure a cleaner, safer work environment.

2. Temperature considerations

Temperature fluctuations can also affect the performance of sandpaper:

Heat resistance: In high-temperature environments, the adhesive used in sandpaper may break down faster, causing premature wear. Choosing sandpaper with heat-resistant properties will help maintain its effectiveness and extend its life.

Cold conditions: Conversely, in cold environments, the flexibility of the sandpaper may be affected. Sandpaper that remains flexible at lower temperatures performs better, providing a more consistent finish.

3. Size and shape of polished area

The specific requirements of the polishing area will also influence the choice of sandpaper:

Polished area: For larger surfaces, a wider sandpaper blade or sanding disc may be more effective and remove material faster. Conversely, smaller or complex areas may require narrower strips or special shapes (such as triangles or circles) to effectively reach tight corners and edges.

Shape of sandpaper: The shape of the sandpaper should match the tool being used and the contours of the surface being polished. For example, if you’re using a hand sander, standard rectangular sandpaper may be enough, but for a detail sander, you may need triangular or finger-shaped sandpaper to get into tight spaces.

4. Specific job requirements

Different projects may have unique requirements that affect sandpaper selection:

Concrete type: The hardness and texture of the concrete you are working on will determine the type of sandpaper required. Softer concrete may require a finer grit, while harder concrete may require a coarser grit for initial grinding.

Desired surface finish: The final appearance of the concrete surface will also influence the choice of sandpaper. If you want a high-gloss finish, you’ll want to start with a coarser grit and gradually transition to finer grits. The environment will affect how quickly you can achieve this finish, so consider the conditions when planning your approach.

Operating Tips and Use of Sandpaper

1. Keep the correct angle

Best angle: For most sanding tasks, a flat angle (approximately 90 degrees) to the surface is ideal. This allows for even pressure distribution and prevents uneven sandpaper wear.

Adjust contour: If you are working on a surface that has a contour or edge, you may need to adjust the angle slightly to ensure full contact between the sandpaper and the surface. This adjustment helps avoid scratches or uneven spots.

2. Apply appropriate pressure

Continuous pressure: Apply constant, moderate pressure while sanding. Too much pressure will cause excessive wear on the sandpaper and may cause scratches on the concrete surface. Conversely, too little pressure may result in poor material removal.

Listen to the tools: Pay attention to the sound and feel of your sanding tools. If it seems to be struggling or makes a lot of noise, it may be a sign that you’re applying too much pressure or that the sandpaper is worn.

3. Replace sandpaper regularly

Signs of wear: Check your sandpaper regularly for signs of wear, such as edge wear or loss of abrasive. Not only is worn sandpaper ineffective, it can also cause unevenness and scratches on the concrete surface.

Regular replacement: Plan to replace sandpaper based on workload. For larger projects, consider replacing the sandpaper after a certain number of square feet or after a specific time interval to maintain optimal performance.

4. Work in sections

Zoning: Divide the concrete surface into manageable sections. This method allows you to focus on one area at a time, ensuring a thorough polish without missing any spots.

Overlap sanding: When sanding, sand with slight overlap to avoid leaving unsanded areas. This technology helps achieve an even polish across the entire surface.

In Conclusion

In summary, choosing the right sandpaper is crucial to ensuring the polishing effect of concrete. By considering factors such as particle size, sandpaper quality, use environment, and operating skills, the polishing work of concrete can be completed more effectively.

Post time: Dec-27-2024