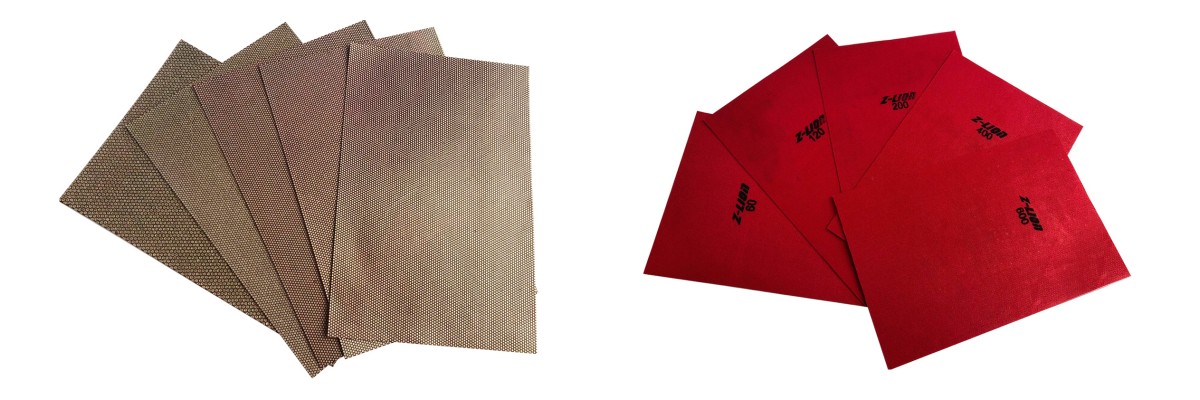

The type of sandpaper you use plays a vital role in achieving a smooth, polished finish on any surface. Sandpaper is classified by its grit, which refers to the coarseness or fineness of the abrasive particles on its surface. The finest types of sandpaper are usually found in 2000 and 3000 grit.

Introduction to the Finest Sandpaper

Grit size and its importance:

The grit of sandpaper is a numerical representation of the size of the abrasive particles. The higher the number, the finer the sandpaper. For example, 2000 grit sandpaper has smaller particles than 1000 grit sandpaper, making it suitable for finer finishing tasks.

2000 grit sandpaper:

2000 grit sandpaper is one of the most commonly used superfine sandpapers. It is ideal for polishing out small dents and imperfections on surfaces such as stone and ceramic. It is also effective at removing residue from paint and coatings, making it a popular choice for automotive refinishing and woodworking.

3000 grit sandpaper:

3000 grit sandpaper is finer than 2000 grit and is primarily used for final polishing and surface finishing. It is particularly effective for achieving a mirror finish on a variety of materials, including metals, plastics, and painted surfaces.

Application Scenarios of 2000 and 3000 Grit Sandpaper

1. Grinding metal surface

Application:

2000 grit sandpaper is particularly effective for sanding metal surfaces that need to be free of rust, scratches, and oxide layers.

Benefit:

Smoother surface: The fine abrasive grains of 2000 grit sandpaper help create a smoother, shinier finish on metal, making it ideal for preparing surfaces for painting or coating.

Versatile: This grit is suitable for use on a variety of metals, including aluminum, steel, and brass, for effective surface preparation in automotive, manufacturing, and repair applications.

2. Sanding wooden surfaces

Application:

When working with wood, use 2000 grit sandpaper to remove burrs and small imperfections from the surface.

Benefit:

Enhance smoothness: Using 2000 grit sandpaper will help to flatten and smooth the surface of the wood in preparation for subsequent finishing or staining.

Pre-treatment: This grit is particularly useful during the final sanding stage before applying varnish or paint to ensure the wood has a perfect finish.

3. Fine grinding of paint surface

Application:

2000 grit sandpaper is also very effective for fine sanding painted surfaces, such as those on cars and furniture.

Benefit:

Imperfection remover: Effectively removes tiny dents, dust particles and residues from the paint surface, leaving a smoother surface.

Improves adhesion: By properly preparing the surface, 2000 grit sandpaper can enhance the adhesion of subsequent layers of paint or clear coat, resulting in a more durable surface.

4. Final polishing

Application:

For final polishing tasks, 3000 grit sandpaper is preferred.

Benefit:

High gloss: This ultra-fine sandpaper is designed to achieve a mirror-like finish on a variety of materials, including metals, plastics, and painted surfaces.

Surface preparation: 3000 grit sandpaper is ideal for final surface treatment to ensure the material is not only smooth but also visually appealing.

Precautions for Using the Finest Sandpaper

1. Apply gently

Wipe gently: When using the finest sandpaper, be sure to apply gentle pressure. Do not use too much force, as this can cause the sandpaper to remove too much material, causing an uneven surface or damaging the workpiece.

Controlled movement: The movements should be smooth and controlled when sanding. This method helps keep the surface smooth and prevents the sandpaper from digging into the material, creating unnecessary scratches or gouges.

2. Personal protective equipment

Wear dust mask: Fine sand creates large amounts of dust, which can be harmful if inhaled. Always wear a dust mask to protect your respiratory system from fine particles.

Use goggles: To protect your eyes from dust and debris, you must wear protective goggles. This protective gear will help protect your vision while working.

3. Pay attention to the direction

Horizontal and vertical orientation: When sanding, pay attention to the direction of sanding. Sanding in an appropriate horizontal or vertical direction will help avoid leaving visible scratches on the surface. When sanding wood, always follow the grain of the material, and when sanding other materials, pay attention to the contours of the surface.

Consistent technology: Maintain a consistent technique throughout the sanding process. This consistency will help ensure an even finish and reduce the risk of visible marks or blemishes.

4. Choose the right sandpaper

Choose the right grit: When using the finest sandpaper, please choose the appropriate sandpaper grit based on the specific material and usage scenario. For example, 2000 grit is great for polishing small dents and imperfections, while 3000 grit is great for final polishing and achieving a high gloss finish.

Important Considerations

Different materials may require different methods. Be sure to evaluate the material you are working with and choose a sandpaper grit that will provide the best results without causing damage.

Post time: Jan-03-2025