Grinding glass edges is an essential skill for anyone who works with glass, whether it’s an art project, repair, or installation. Properly ground edges not only enhance the appearance of your glass but also ensure safety by eliminating sharp, jagged edges. Here are some tips and methods, along with the necessary tools, to help you achieve a smooth, polished glass edge.

Prepare Your Tools

Before you start grinding glass edges, it’s crucial to gather the right tools. Here’s a list of basic items you’ll need:

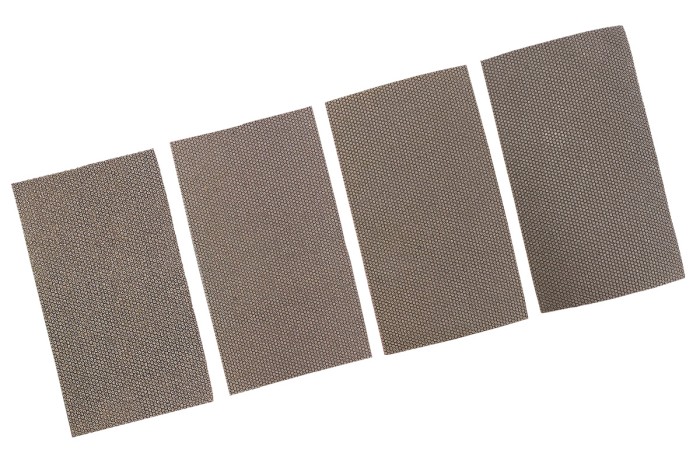

1. Sandpaper:

Grit size: The finer the sandpaper, the better the finish. For glass, it is recommended to use 600 or 800 grit sandpaper.

Wet sanding: Consider wet sanding, which involves moistening the sandpaper. This technology helps reduce dust and keeps the glass cool, minimizing the risk of breakage.

2. Grinder:

There are two common types of grinders:

Electric grinder: These machines are powerful and efficient, making them ideal for larger projects or thicker glass. They often come with a variety of attachments for different grit levels, allowing for versatility in finishing.

Hand grinder: These grinders are more affordable, offer more control, and are suitable for detailed work on smaller projects. While they require more physical labor, they can be just as effective if used correctly.

3. Plastic scraper:

After grinding, a plastic scraper must be used to remove chips and sharp debris from the edges of the polished glass. Hold the scraper at a slight angle to the edge of the glass and gently scrape away any remaining particles. This step is critical to ensure a smooth finish and prepare the glass for further processing or installation.

4. Metal blade scraper:

Feature: The metal blade scraper can be used to address any scratches that may occur during the grinding process.

Technical: Use the metal scraper carefully and apply gentle pressure to avoid damaging the glass. Focus on the scratched area until it is smoothed, making sure the edges are polished and flawless.

Steps to Polish Glass Edges

1. Prepare your workspace:

Make sure your work surface is clean and flat. A stable surface is essential for achieving a uniform polishing result. Gather all the necessary tools, including fine sandpaper, a grinder, a scraper, and a cleaning cloth.

2. Preliminary polishing with fine sandpaper:

Place the edge of the glass on a flat work surface. Use fine sandpaper (600 or 800 grit is best) to lightly sand the edges.

Technique: Use a circular or back-and-forth motion, applying light pressure. This initial step helps smooth out any rough spots and prepares the edges for further shaping.

3. Use grinder to shape:

If you need to trim the edge of the glass, use a grinder. Start with coarse sandpaper to remove more material and shape the edges as desired.

Transition to fine sandpaper: Once the edges are shaped, gradually transition to finer sandpaper (600 or 800 grit) to refine the edges and achieve a smooth surface.

Safety tip: Always wear goggles and a face shield when using the grinder to protect against glass dust and debris.

4. Check flatness:

After forming and polishing, check the flatness of the glass edges. Look for any gaps, cracks, or scratches that may have appeared during the grinding process.

If you find imperfections, use a scraper (metal blade scraper) to carefully remove any scratches or rough spots. This step is crucial to ensure a perfect finish.

5. Clean polished edges:

Use a plastic scraper to remove any chips or glass particles from the polished edges. This will help ensure the surface is clean and flat.

Technical: Hold the scraper at a slight angle and gently scrape away any remaining particles without scratching the polished surface.

6. Final polishing:

After cleaning, sand the edges of the glass again with fine sandpaper. The final step will enhance the smoothness and shine of the edges.

Technique: Use light pressure and consistent movements to achieve an even finish. Wet sanding is also beneficial at this stage to reduce dust and improve the finish.

7. Final inspection and cleaning:

When you are finished polishing, wash the glass plate with mild soap and water to remove any remaining dust or debris.

Check the edge of the glass carefully to make sure it is intact and free of any defects. If necessary, repeat any steps to achieve the desired effect.

Important Notes on Grinding Glass Edges

1. Avoid using sandpaper that is too rough

Using sandpaper that is too coarse can leave unsightly marks on the glass surface. Choosing the right granularity for your project is crucial. For glass, it is recommended to start with finer sandpaper, such as 600 or 800 grit sandpaper, to minimize the risk of scratches and ensure a smooth surface. If you need to remove more material, consider using a coarse-grit grinder, but always transition to a finer grit for polishing.

2. Check the flatness regularly

During the grinding process, it is crucial to frequently check that the edges of the glass are flat. This step helps avoid issues like gaps, unevenness, or falling corners. Use a ruler or level to evaluate the flatness of the edges of the glass. If you notice anything unusual, address it immediately to prevent further complications.

3. Apply even pressure

When grinding, it is important to apply force evenly around the edge of the glass. Uneven pressure can cause overgrinding in certain areas, which can affect the thickness and strength of the glass. Take your time and use consistent movements to make sure the edges are sanded evenly. This method not only improves the quality of the finish, it also helps maintain the integrity of the glass.

4. Safety first

When working with glass, safety is always a top priority. When using a grinder or any other power tool, always wear appropriate protective gear, including gloves, goggles, and a dust mask. This gear will help protect you from glass shards, dust, and potential injuries. Additionally, work in a well-ventilated area to minimize exposure to harmful particles.

Post time: Nov-11-2024