When polishing surfaces, especially hard materials such as concrete, stone, metal, glass, and ceramics, the choice of tool can significantly affect the quality of the finish. Two tools commonly used in the polishing process are diamond polishing pads and sandpaper. While both are used to smooth and refine surfaces, they have unique characteristics, benefits, and applications. This article will explore the differences between diamond polishing discs and sandpaper.

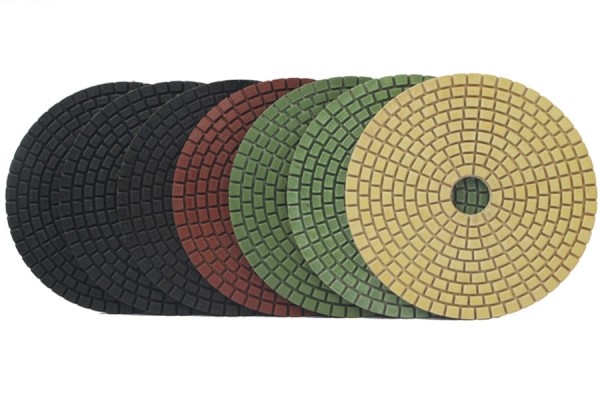

Diamond Polishing Pads

Composition and structure

Diamond polishing pads are specialized tools composed of a combination of binder, diamond particles, and powder. The diamonds used in these discs are natural minerals known for their exceptional hardness, rated 10 on the Mohs scale. This makes them the hardest known materials, allowing them to effectively grind and polish the hardest surfaces.

Advantages

1. Durable: Diamond polishing pads are highly wear-resistant and suitable for widespread use. They can withstand high temperatures and maintain their effectiveness over time, resulting in a longer service life than traditional abrasives.

2. Precision: The fine structure of the diamond polishing pad allows for a more refined polishing process. They achieve a high level of detail and smoothness, making them ideal for applications that require a superior finish.

3. Versatility: These grinding discs are suitable for use on a variety of materials, including hard metal, stone, glass, and ceramics. Their ability to handle a variety of surfaces makes them a versatile choice for professionals in different industries.

Application

Diamond polishing discs are commonly used in industries such as construction, manufacturing, and automotive. They are particularly effective on polished concrete floors, granite countertops, and glass surfaces (where a high gloss finish is required).

Sandpaper

Sandpaper is a widely used abrasive tool that has been a staple in various industries and DIY projects for years. Sandpaper consists of a paper backing coated with abrasive particles designed to smooth the surface, remove material, and prepare the surface for surface preparation.

Composition and structure

1. Backing material: The backing is usually made of paper, but can also be made of cloth or other materials. The choice of backing affects the flexibility and durability of the sandpaper.

2. Abrasive particles: The surface of the sandpaper is coated with abrasive particles, which can be made of a variety of materials, including alumina, silicon carbide, diamond, etc. The size of these particles determines the grit size of the sandpaper, thereby affecting its grinding accuracy and effectiveness.

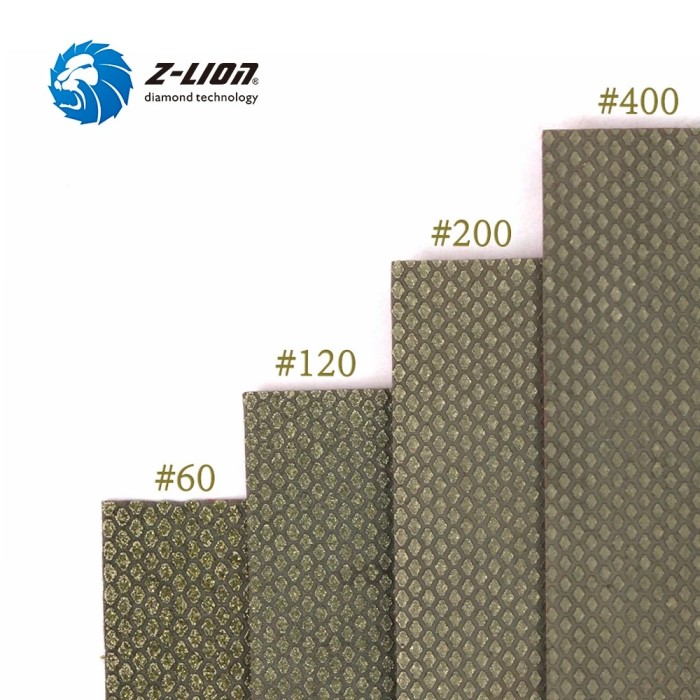

Granularity and its impact

Coarse grit (30-60): Ideal for removing heavy materials and shaping surfaces. Coarse grits are very effective for the initial sanding of rough surfaces.

Medium grit (80-120): Suitable for smoothing surfaces and preparing them for finer sanding. Medium grit is usually used for intermediate sanding.

Fine grit (200-400): For final sanding and achieving a smooth surface. Fine-grit grit is very effective for polishing the surface before applying the finish.

Ultra-fine grit (400 and above): For ultra-smooth finishes and polishes. Ultra-fine grit is ideal for finishing surfaces.

Advantages of sandpaper

1. Affordable: Sandpaper is often more cost-effective than specialized polishing tools like diamond polishing discs. This makes it a convenient choice for DIY enthusiasts and home improvement projects.

2. Easy to use: The sandpaper is lightweight and easy to handle, making it suitable for manual polishing tasks. It can be cut to size and used with a variety of hand tools or power tools.

3. Versatility: Sandpaper can be used on a variety of materials, including wood, metal, plastic, and drywall. Its versatility makes it a valuable tool for a variety of applications.

Choice Between Diamond Polishing Pads and Sandpaper

1. Consider materials

For hard materials: If you are polishing hard materials like concrete, or granite, a diamond polishing pad is a better choice. Their hardness and durability allow them to effectively grind and polish these surfaces, resulting in a high-quality finish.

For softer materials: If you are working with softer materials, sandpaper will suffice. It provides adequate smoothness and finishing without requiring the specialized functionality of a diamond pad.

2. Assess required polish

High quality polishing: If a fine, high quality polish is required, such as for fine woodworking or high-end stonework, diamond polishing pads are recommended. They can achieve a smoothness and gloss that sandpaper may not be able to match.

General polishing needs: For home polishing tasks that do not require ultra-fine polishing, sandpaper can achieve satisfactory results. It is very effective for general surface preparation, smoothing, and finishing.

3. Budget and accessibility

Cost considerations: If budget constraints are an issue, sandpaper is usually cheaper and can be purchased at most hardware stores. This is an excellent choice for casual users or those working on small projects.

Professional use: For professionals or those working on a wide range of polishing projects, it may be worthwhile to invest in diamond polishing pads due to their long life and superior performance.

How to Use Diamond Polishing Pads and Sandpaper Correctly?

1. Start with rough tools

For inexperienced users, it is recommended to start with coarse sandpaper or a diamond polishing pad:

Initial processing: Start processing the workpiece surface with coarse sand. This initial step helps remove rough spots, imperfections, and material quickly. Rough grinding tools effectively shape and prepare surfaces for finer polishing.

Gradual transition: After the initial grinding or polishing, gradually transition to finer tools. This step is critical to achieving a smooth completion. Using increasingly finer grits or pads allows for better refinement and minimizes the risk of damaging the surface.

2. Maintain appropriate rotation speed

Best speed: Make sure your polisher or tool is set to the appropriate speed. Speeds that are too low may result in poor polishing results, while speeds that are too high may cause excessive wear on the tool and workpiece.

Use auxiliary tools: Using a polishing machine or other auxiliary tools can help maintain consistent speed and pressure during the polishing process. This not only improves efficiency but also improves the quality of the finished product.

3. Keep the sandpaper clean

Clean up debris: Periodically check the back of the sandpaper for loose sand or debris. Accumulated particles reduce friction and hinder the polishing process. Gently tap or brush away any loose material to maintain the effectiveness of the sandpaper.

Check for wear: Monitor the condition of the sandpaper while working. If it’s clogged or worn, replace it with a new part to ensure consistent results.

4. Safety first

Protective equipment: Wear appropriate protective gear, including gloves and goggles, to protect against dust, debris, and potential injury. This is especially important when using power tools, as they generate large amounts of dust and particles.

Work environment: Make sure your workspace is well-ventilated and free of hazards. A clean and tidy area will help you stay on task and reduce the risk of accidents.

Post time: Nov-01-2024