The textile emery industry plays a vital role in the textile manufacturing industry, providing essential tools and materials for fabric finishing processes. Emery is a granular rock composed of corundum and magnetite, which is widely used in the production of abrasives. In the textile industry, sandpaper-coated tools are primarily used in the “sanding” or “sandpapering” process, which involves brushing the surface of a fabric to produce a soft, velvety texture. The process is particularly popular when producing fabrics such as flannel, microfiber and other materials that require a soft feel.

Discover the Magic of Textile Emery!

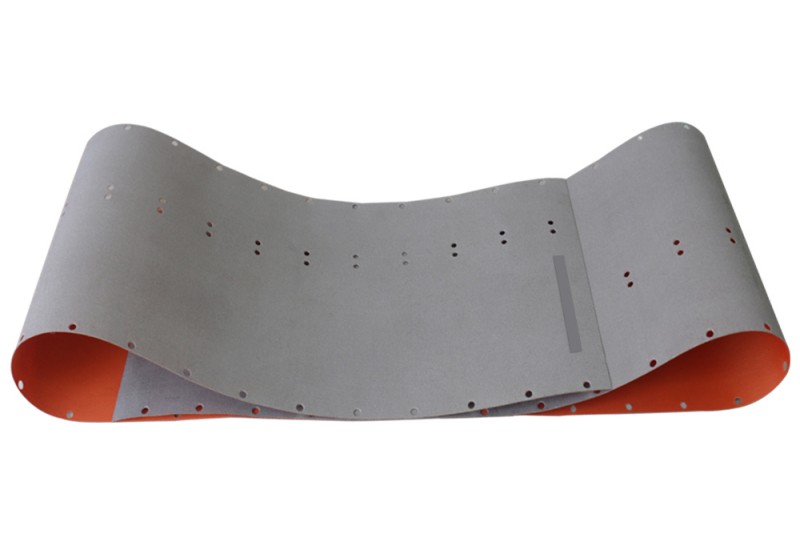

Are you in the textile industry and looking to elevate your fabric finishing game? Textile Emery tools are your secret weapon for achieving that perfect, velvety texture on fabrics like flannel and microfiber. Whether you’re in fashion, home textiles, or automotive interiors, our high-quality emery-coated rollers and belts ensure a soft, luxurious finish every time.

Raising Process

Sanding is a specialized finishing technique that improves the tactile feel of a fabric. By using an emery-coated tool, manufacturers can effectively remove the top layer of fibers from the surface of a fabric, creating a plush, soft texture. This process not only improves the aesthetics of the fabric, it also enhances its performance characteristics, such as breathability and moisture absorption.

Applications: Suede treatment is commonly applied to a variety of textiles including apparel, upholstery and home textiles. Fabrics treated with this treatment are sought after for their luxurious feel and visual appeal, making them a popular choice in the fashion and interior design industries.

Why Choose Textile Emery?

1. Durability: long-lasting performance to ensure continuous production

One of the outstanding features of textile emery products is durability. Sandpaper-coated tools are made of high-quality materials and can withstand the rigors of continuous production.

Extended service life: The robust nature of the diamond materials ensures they can withstand repeated use without severe wear. This long life means lower replacement costs and less downtime in your manufacturing process.

Stable performance: Durable emery tools maintain their effectiveness over time, providing consistent results throughout the production cycle. This reliability is essential for manufacturers who require high-quality textile surface treatments.

2. Precision: Consistently perfect results

Precision is critical in the textile industry, where the quality of the end product can significantly impact customer satisfaction and brand reputation.

Uniform texture: Textile emery tools are engineered to provide an even surface finish, ensuring fabrics achieve the desired softness and texture. This is especially important in applications such as suede where a consistent velvety feel is essential.

Reduce defects: The precision provided by diamond-coated tools minimizes the risk of defects during the finishing process. This produces higher quality textiles that meet the stringent standards of industries such as fashion and home textiles.

3. Innovation: Cutting-edge technology for superior fabric treatment

The textile emery industry is evolving with major players investing in research and development to enhance the performance of their emery products.

Advanced formulations: Innovations in diamond coatings and formulations drive tool development, improving efficiency and effectiveness. These advances help manufacturers keep pace with changing market demands and consumer preferences.

Enhanced versatility: Modern emery tools are designed to handle a wide range of fabrics and finishes, making them suitable for a variety of applications. This versatility allows manufacturers to adapt to different production requirements without compromising quality.

What Is a Diamond Emery Tape?

Diamond emery tape is an abrasive product with diamond grit as the abrasive material bonded to a flexible backing, usually made of cloth. Diamond grit is the hardest known natural material, which makes diamond emery tapes extremely effective in grinding, sanding and polishing tasks, especially on hard materials.

Granularity and flexibility

Diamond emery tape comes in various grit sizes, which determine the intensity of the polish and the smoothness of the surface.

Coarse grit: Used for rapid material removal, coarse grit is ideal for initial shaping and grinding tasks.

Fineer grit: Finer grit is used for finishing and polishing, providing a smooth and refined surface.

The tape’s flexibility allows it to conform to complex shapes and contours, making it suitable for a wide range of applications.

Backing materials and adhesives

Diamond emery tape varies in backing material, with some designed to be more flexible for intricate work and others to be more rigid for stability. The adhesive used to bond the diamond grains to the backing is also critical in determining the performance of the tape. It must be strong enough to hold the diamonds in place during use while allowing for consistent wear and effective polishing action.

Application of Diamond Emery Tape

Diamond emery tapes are used in a variety of industries, including glass, cloth, ceramics, carbides, alloys and gemstone processing. Their unique properties make them particularly suitable for:

Grinding and polishing: Diamond emery tapes can effectively grind surfaces to a high degree of smoothness and gloss. This is essential in applications where aesthetics and surface quality are critical.

Grinding and shaping: The tape can shape hard materials, including ceramics and glass, making it a valuable tool in manufacturing processes that require precision and efficiency.

Market Growth and Demand

The global textile abrasive tools market is witnessing steady growth driven by the growing demand for high-quality finished textiles across industries such as fashion, home textiles, and automotive interiors. As consumers become more particular about the quality and feel of the fabrics they purchase, manufacturers are forced to invest in advanced finishing technologies to enhance the overall product quality.

Innovation and development: Key players in the textile emery industry are constantly innovating to improve the durability and efficiency of sandpaper rolls and sandpaper belts. This includes developing new formulations and coatings to enhance the performance of these tools, ensuring they meet the changing needs of textile manufacturers. Innovation may also focus on reducing wear, extending the life of the tool, and improving the consistency of the finishing process.

Environmental Considerations

Like many industries, the textile emery industry is facing increasing scrutiny for its environmental impact. Manufacturers are exploring sustainable practices, such as using environmentally friendly materials and processes to minimize waste and energy consumption. The drive for sustainability is becoming an important factor in the decision-making process for manufacturers and consumers.

Sustainable practices: Companies are investing in research and development to create more environmentally friendly placer products and processes. This includes exploring alternative materials and methods that reduce the ecological footprint of textile finishing operations.

In Conclusion

Choosing textile emery products, including diamond emery tape, offers numerous advantages to manufacturers in the textile industry. The durability, precision and innovative designs of these tools are essential for achieving high-quality finishes on a wide range of fabrics. As the textile industry continues to evolve, the importance of reliable and effective abrasive paper products will only grow, and they are a vital investment for any textile manufacturer looking to improve their production processes.

Post time: Mar-28-2025