-

Diamond tool electroplating Diamond tool plating is the process of electrodepositing a base metal (such as nickel or cobalt) onto a substrate (such as steel) to firmly surround the diamond particles. This electroplated diamond tool offers several benefits, including excellent wear resistance, h...Read more »

-

When it comes to creating perfectly smooth and rounded edges on stone surfaces, the use of burrs has become one of the most widely adopted techniques. This method provides a reliable solution for professionals seeking to achieve the perfect polish on stone, taking into account factors such as thi...Read more »

-

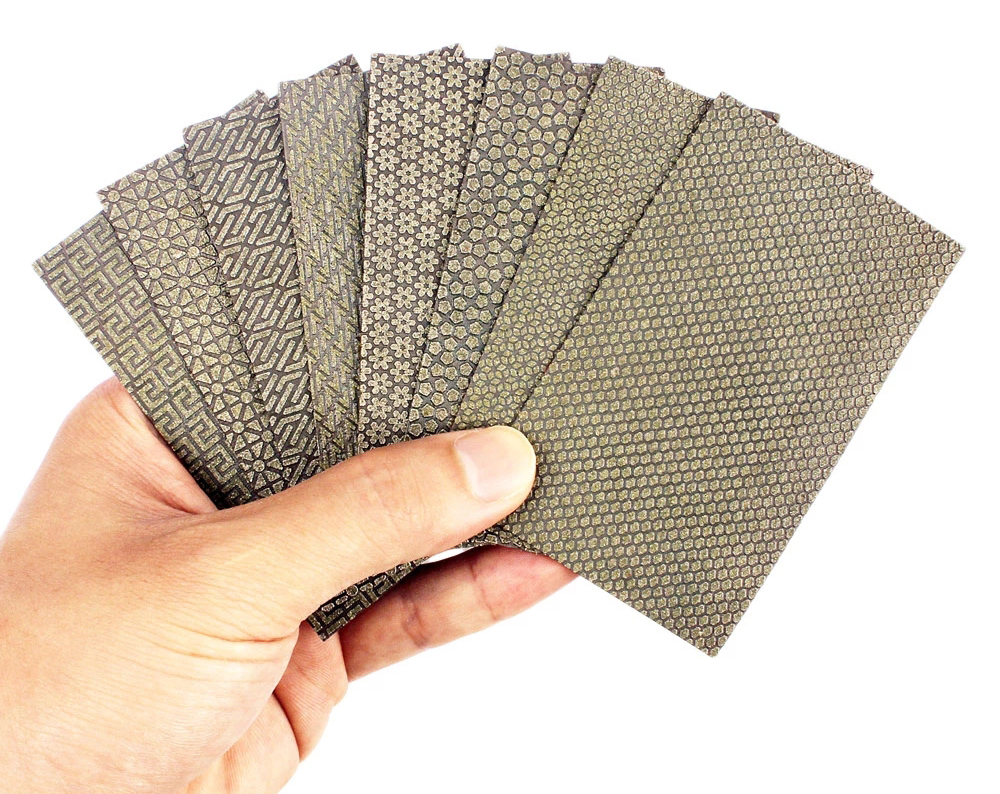

Characteristics of electroplated diamond sanding discs Electroplated diamond sanding discs have become the first choice for professionals looking for efficient, precise grinding tools. Made using a unique electroplating process, these discs have many properties that make them essential for machin...Read more »

-

From innovative architectural designs to professional applications, glass has become a versatile material that plays an irreplaceable role in many special occasions. A key factor in maintaining the luster of glass is the correct polishing technique. Whether it’s a delicate piece of art or ...Read more »

-

The continuous development of new materials pushes the boundaries of machining, achieving high quality, high precision, high efficiency, and increased automation. Electroplated diamond grinding discs have received widespread attention due to their excellent performance in processing various mater...Read more »

-

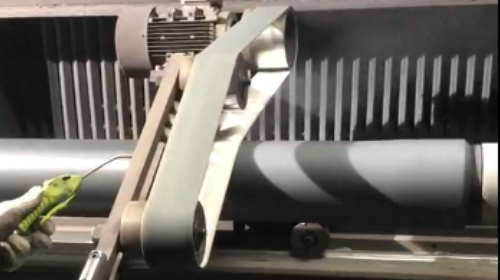

What is sanding belt life? Sanding belt life refers to the time that an abrasive belt can maintain its grinding function under normal use conditions. The life of the sanding belt is related to many factors such as the quality, material, structure of the abrasive belt, the processing status of th...Read more »

-

Proper maintenance of sanding belts is very important to ensure their longevity and performance in wet weather conditions. Whether you’re using them for woodworking or metalworking, following these guidelines will help you maintain the quality of your sanding belts, even in wet conditions....Read more »

-

Basic concepts of grinding disc and flap disc Grinding disc Composition: Abrasive discs, also known as grinding wheels, are round tools composed of abrasive grains, binders, fillers, etc. Abrasive grains, usually made of materials such as aluminum oxide, silicon carbide or diamond, provide the cu...Read more »

-

Safety and Environmental Protection To ensure safety and protect the environment during sanding, follow these guidelines: Wear a mask: Always wear a mask to protect yourself from inhaling dust particles. Use protective gear: Dust can be harmful to the skin when working with materials such as c...Read more »

-

Glass is a ubiquitous material in our daily lives, found in windows, mirrors and various electronic devices. To meet the needs of different applications, glass materials are usually processed by various techniques, including cold working. In this article, we explore the concept of cold working of...Read more »

-

Abrasive belt grinding has the characteristics of high efficiency, high economy and wide application range, and is increasingly valued by all walks of life. In order to make better use of the advantages of abrasive belt grinding and keep the abrasive belt in good condition during use, Z-LION has ...Read more »

-

An angle grinder is mainly used for cutting and grinding glass and is also widely used in woodworking, bricklayer, welding, and other industries. So what is its use? What are the precautions for use? Let Z-LION tell you about this knowledge. How to use the angle grinder? Angle grinders are versat...Read more »