-

The edging process has proven to be an important technology in the glass manufacturing industry, not only enhancing the visual appeal of glass but also significantly improving its safety and durability. This meticulous craftsmanship has become the cornerstone of providing glass products that mee...Read more »

-

The critical role of glass edge treatments in improving safety and quality When it comes to glass processing, the edge treatment of the glass plays a key role not only in its visual appeal but also in the overall safety and durability of the material. The meticulous process of glass edge prepa...Read more »

-

The abrasive tool industry has experienced significant growth in recent years, especially with the increasing popularity of angle grinders. Also known as an angle grinder, this tool has become a staple in hardware manufacturing and stone grinding. Its handheld design offers convenience, but its ...Read more »

-

Glass edging is an important process in various industries and requires a series of meticulous skills and preparation to achieve excellent results. As demands for precision and quality continue to increase, mastering the secrets of glass edge grinding is vital for professionals in the field. Her...Read more »

-

Belt sanders are an essential part of various industrial and woodworking operations, helping to smooth and shape materials with precision and efficiency. However, the occurrence of left-to-right rocking of the sanding belt hinders the efficiency of the machine and affects the quality of the sandi...Read more »

-

Concrete’s affordability, high formability, and exceptional durability make it a favored material for homes looking to optimize space and enhance the functionality of their kitchens. One of the main attractions of concrete countertops is their ability to fit into a variety of kitchen layout...Read more »

-

Metal polishing Metal paint polishing is a technique used to refine metal surfaces after painting, playing a key role in enhancing durability and overall expression. This meticulous process involves grinding and modifying metal surfaces to eliminate defects and burrs, thereby improving smoothness...Read more »

-

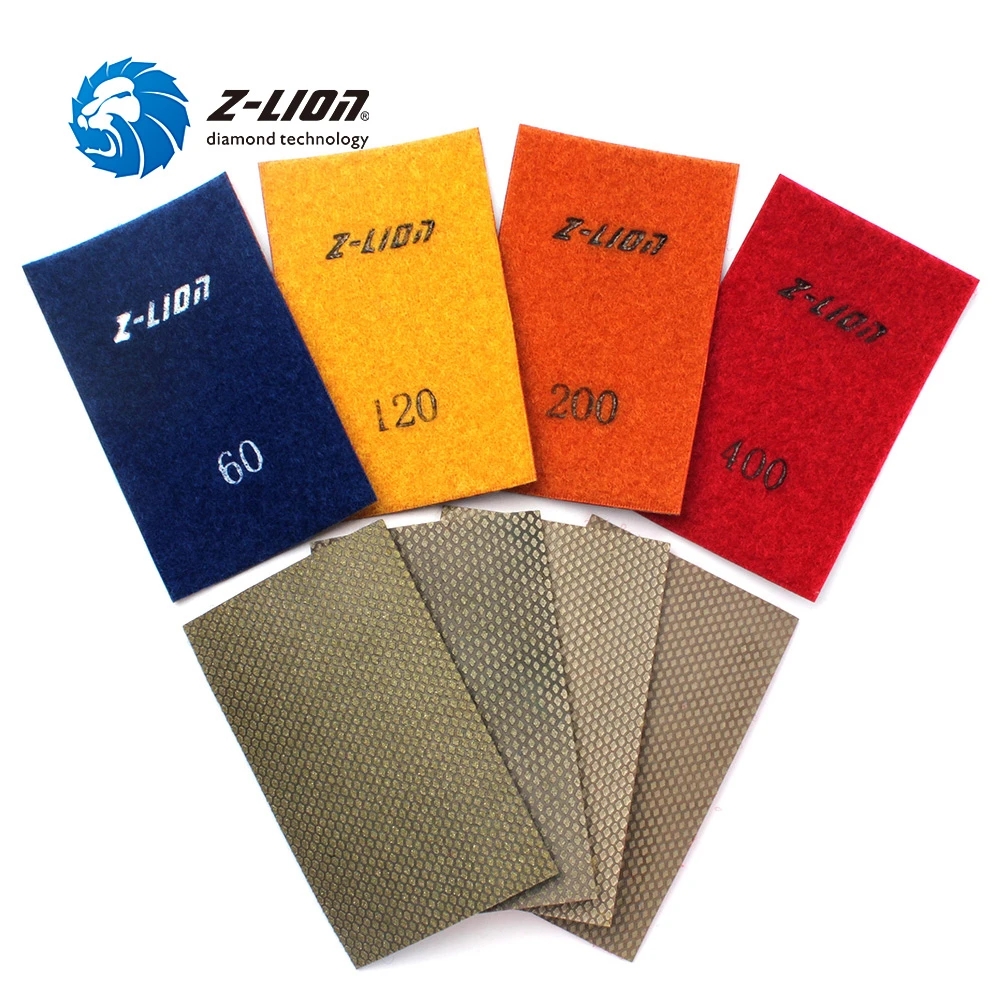

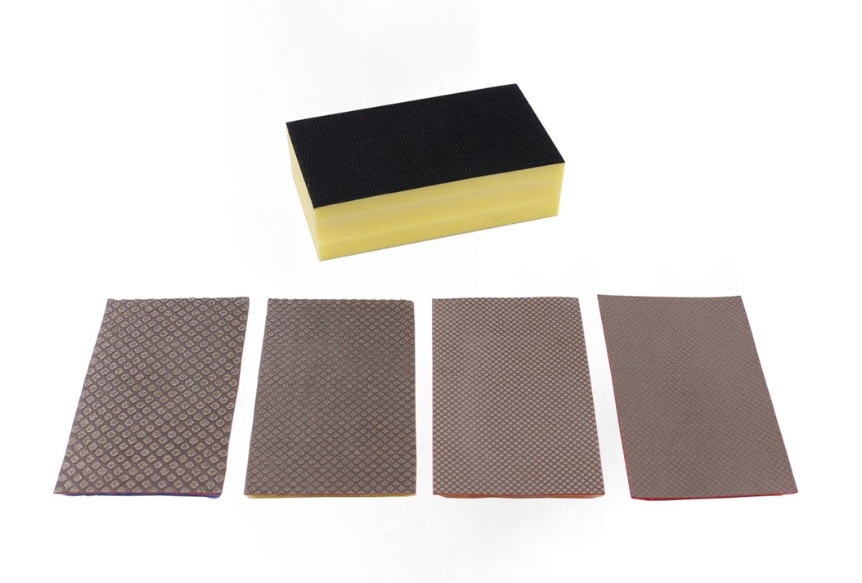

Materials are different Unlike regular sandpaper, diamond sandpaper harnesses the power of synthetic diamond particles. With high hardness and excellent wear resistance, diamond sandpapers have a longer service life. Traditionally, sanding was a laborious process that often required frequent ...Read more »

-

Glass surfaces are prone to scratches, whether from accidental impacts or long-term wear and tear. These unsightly marks can be very unsightly and detract from the overall beauty of the glass object or window. Luckily, there’s a simple do-it-yourself solution that can help restore glass to ...Read more »

-

When it comes to tile installation, achieving a perfect finish is crucial. However, even with great care, tile edges can sometimes become damaged or uneven. The good news is there’s a simple solution: sandpaper. With a few strategic steps, you can use sandpaper to smooth down the edges of y...Read more »

-

Meet the higher requirements of electroplated diamond tools in the abrasives industry With the continuous development of the abrasives industry, the requirements for electroplated diamond tools have reached new heights. Manufacturers and users alike require tools with high efficiency, long life a...Read more »

-

Diamond tool electroplating Diamond tool plating is the process of electrodepositing a base metal (such as nickel or cobalt) onto a substrate (such as steel) to firmly surround the diamond particles. This electroplated diamond tool offers several benefits, including excellent wear resistance, h...Read more »