-

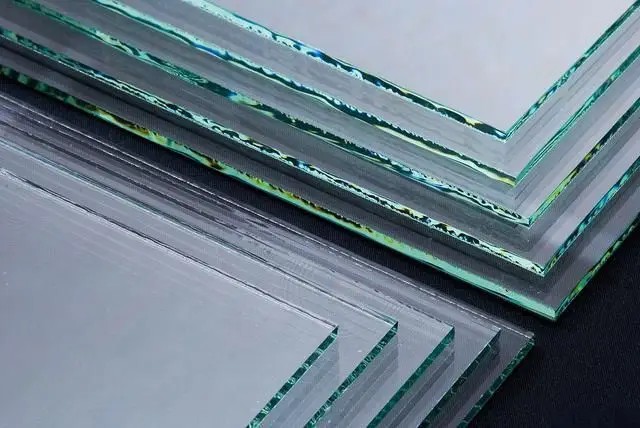

Glass products are everywhere in our daily lives, from glasses and mirrors to decorations and windows. However, due to improper handling or accidental collisions, the edges of glass products can become sharp, posing a risk of injury. Polishing these sharp edges is essential for safety and aesthet...Read more »

-

Marble and granite are popular choices for home decor and construction because of their unique beauty, durability, and resistance to wear. However, despite their hardness, these natural stones can develop cracks, scratches, or other forms of damage over time. Promptly repairing these imperfection...Read more »

-

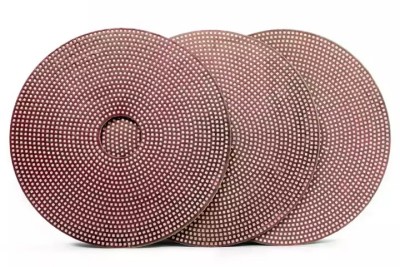

The type of sandpaper you use plays a vital role in achieving a smooth, polished finish on any surface. Sandpaper is classified by its grit, which refers to the coarseness or fineness of the abrasive particles on its surface. The finest types of sandpaper are usually found in 2000 and 3000 grit. ...Read more »

-

When sanding concrete, choosing the right sandpaper is essential to achieving a smooth, polished surface. The size and grit of the sandpaper plays a major role in the effectiveness of the sanding process. Here is a detailed guide on how to choose the right sandpaper for sanding concrete. Choice...Read more »

-

Overview Ceramic is a versatile material known for its durability, beauty, and long life. It is used in a wide range of applications, from manufacturing to home decoration. However, over time, ceramic surfaces can develop wear, scratches, and stains that compromise their appearance and functional...Read more »

-

Artificial Marble Surface Characteristics Artificial marble, also known as engineered stone, is a popular material for both residential and commercial applications. Made from natural stone particles combined with a man-made resin, it offers a range of benefits that make it ideal for a variety of ...Read more »

-

Glass cup processing presents unique challenges due to the inherent brittleness and susceptibility to cracking of the material. Therefore, selecting the right cutting tool is critical to achieving high-quality results and minimizing waste and damage. Diamond tools have become the preferred soluti...Read more »

-

With the continuous advancement of industrial technology, precision grinding has become increasingly important in various fields such as aerospace, automobile, electronics, and medical device manufacturing. Among the essential tools for precision grinding, electroplated diamond grinding wheels ha...Read more »

-

Principles for Selecting Sanding Belt Width When it comes to using sanding belts effectively, one of the key factors to consider is the width of the abrasive belt. The selection of width should be based on the specific processing requirements and the shape and size of the object being processed. ...Read more »

-

Diamond grinding wheels are essential tools in the glass processing industry, known for their high precision and smoothness. However, the finish of ground glass is sometimes substandard. This article will analyze the main reasons for insufficient finish when using diamond grinding wheels, and pro...Read more »

-

Grinding glass edges is an essential skill for anyone who works with glass, whether it’s an art project, repair, or installation. Properly ground edges not only enhance the appearance of your glass but also ensure safety by eliminating sharp, jagged edges. Here are some tips and methods, al...Read more »

-

When polishing surfaces, especially hard materials such as concrete, stone, metal, glass, and ceramics, the choice of tool can significantly affect the quality of the finish. Two tools commonly used in the polishing process are diamond polishing pads and sandpaper. While both are used to smooth a...Read more »