Diamond flap discs are designed to be mounted on hand-held power tools and are used in a variety of applications including weld grinding and polishing, burring, chamfering, surface dusting, and surface polishing of metallic and non-metallic parts. With their unique features and numerous advantages, flap discs have become the first choice of many professionals over traditional bonded abrasive resin grinding wheels.

First, they have the ability to fine-grind and polish at the same time. This eliminates the need for multiple tools or steps, significantly reducing operator time and increasing efficiency. With flap discs, manufacturers can complete the entire finishing process in one pass, simplifying production and saving valuable time and resources. In addition to their time-saving benefits, flap discs are also known for their cost-effectiveness. Diamond flap discs significantly reduce grinding costs by eliminating the need for separate grinding and polishing steps. Combined finishing features allow for a more streamlined workflow, reducing the need for additional equipment or consumables. This cost-saving advantage has attracted businesses across industries, enabling them to allocate resources more efficiently.

An outstanding feature of the diamond flap discs is their powerful self-sharpening ability. During the grinding process, the abrasive on the fins continuously exposes new cutting edges. This self-sharpening feature ensures consistent and efficient material removal for optimum performance throughout its service life. As a result, operators benefit from increased productivity and increased usage time, resulting in less downtime for changing worn tools. In addition, the use of flap discs minimizes the risk of surface damage due to their air-cooling capabilities. Unlike other grinding wheels that can generate too much heat and cause the surface to burn or deform, the thousand-petal disc dissipates heat efficiently through its design. This prevents damage to the workpiece surface, ensuring a higher level of precision and quality during grinding and polishing. This feature is especially beneficial when working with delicate or heat-sensitive materials. Surface quality can be controlled more easily with flap discs. The flexible structure of the flap allows the operator to adjust the pressure and angle according to the desired surface finish. This level of control ensures consistent and precise results for a wide variety of applications. Operator fatigue is also reduced when using flap discs. The ergonomic design and low weight of the handheld power tool, combined with the efficient and smooth operation of the flap discs, reduces operator stress. This helps maintain productivity and reduces the risk of injuries and fatigue-related errors, creating a safer and more comfortable work environment.

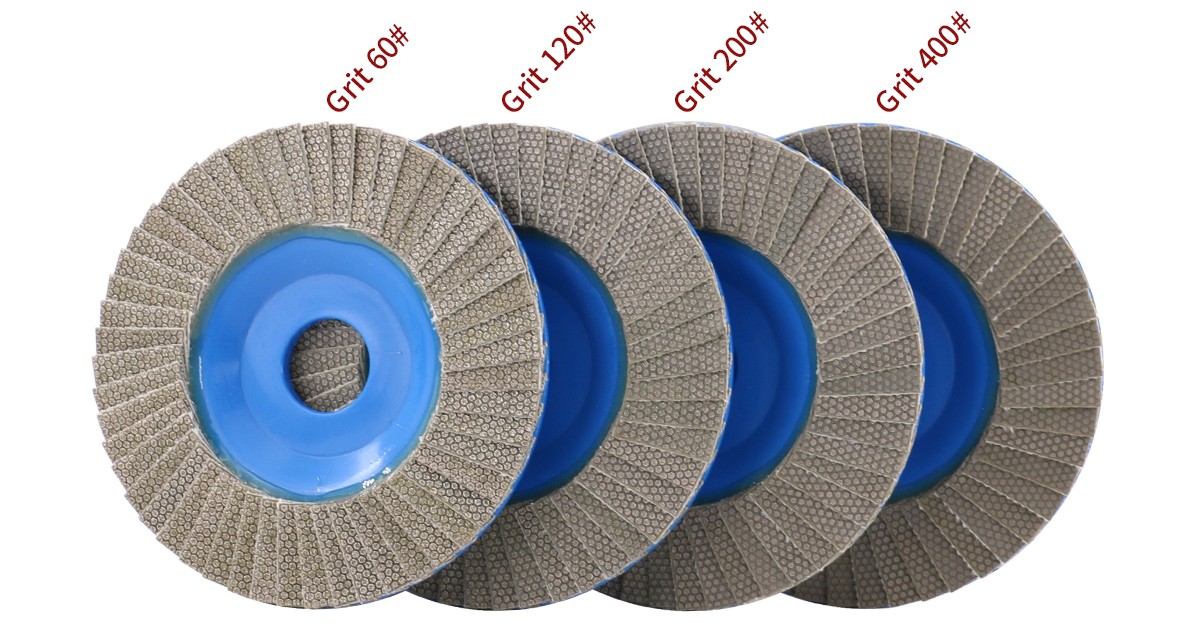

The core foundation of a diamond flap disc in its base, which can be made of a variety of materials, including mesh, nylon, plastic, steel paper, and more. Each substrate has unique properties that enable superior performance in different scenarios. The fan-shaped structure of the diamond flap disc can evenly distribute the grinding and polishing discs. This thoughtful design ensures consistent contact with the workpiece for precise and efficient finishing.

4 Points for attention when storing the flap discs

1. Climate-Controlled Storage: The flap disc should be stored in a dry place at a room temperature not lower than 5°C. Exposure to excessive humidity or extreme temperatures may compromise the integrity of the disc. Moisture can cause corrosion while freezing temperatures can cause cracking or deformation. Therefore, it is critical to provide a climate-controlled environment to safeguard the quality and longevity of flap discs.

2. Avoid Oil and Moisture: Flap discs should never be placed in wet or freezing areas and should be kept away from oil, grease, or any other substance that could reduce their strength and abrasive power. Oil or grease residue can contaminate the abrasive, reducing its effectiveness. As mentioned earlier, moisture can cause corrosion or affect the bond of the abrasive material to the disc. Therefore, it is critical to store your flap disc in an area that is clean, dry, and away from potential sources of contamination.

3. Storage time limit: Flap discs should not be stored for longer than one year. Over time, the abrasive material on the disc degrades, resulting in reduced performance.

4. They should be placed separately according to the specifications, and the storage places should be marked to avoid confusion and mistakes. The placement method should depend on the size of the grinding shape. Abrasives with large diameter or thicker diameter should be placed upright and slightly inclined, and thinner and smaller grinding wheels should be placed in a flat stack, but not too high, and a flat iron plate should be placed on the top and bottom of the flap discs to prevent deformation of the flap disc or rupture.

Post time: Jul-06-2023