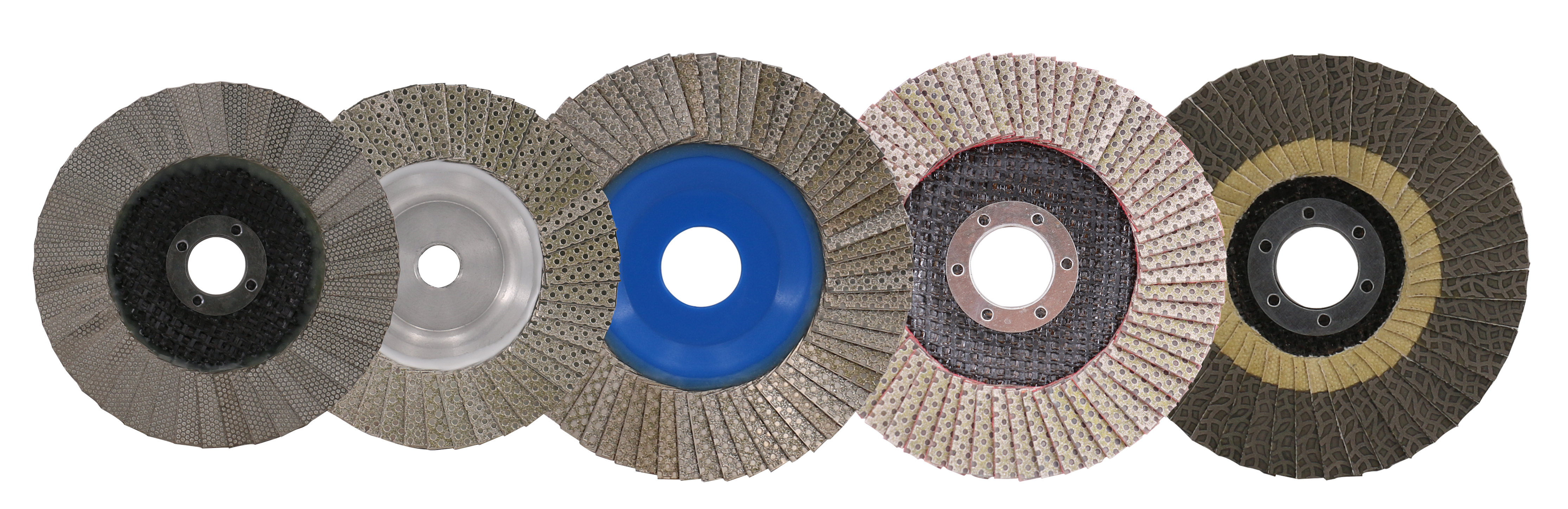

Diamond flap discs are becoming more and more popular in the industry of stone and construction. They are commonly used on hand-held electric or pneumatic angle grinders for sanding, grinding, shaping and smoothing of natural stone, ceramic, porcelain stoneware, concrete, glass etc. Because of this increased popularity, it is good to have a safety guide for diamond flap discs, focusing on the three areas where most problems may arise.

1. Proper Grinding Angle

It is important to use diamond flap discs at the correct angle. Using flap discs at incorrect angle can cause glue melting, backing damage, or snagging. All of these can lead to separation of the diamond flaps or even flap flying which would cause serious damage on the material it is sanding or even injure the operator. Type 27 flap discs should be used at 0°-15° angle and Type 29 flap discs should be used at 15°-25° angle.

2. Guards

There is a common misconception that guards are not required when using coated diamond abrasive products which are kind of flexible. This is simply not true. Actually, if the machine is designed and equipped with guards, it shall not be operated without the guards properly installed and in place. Diamond flap discs are designed for use on angle grinders, which come equipped with guards. The guard is designed to contain the pieces and protect you from injury in case of backing breakage or flap separation. So make sure your grinder has the proper guard, that it is in good condition, and that it is positioned between you and the flap disc.

3. Inspection

Inspect diamond flap discs for any signs of damage on both the backing and the diamond working surface prior to using. A diamond flap disc that has been dropped or mishandled can be damaged, which can lead to breakage or flap separation. Do not use a diamond flap disc that has been damaged.

Besides above three areas, it is also important to check machine speed against established safe operating speed marked on diamond flap disc, and to wear proper personal protection such as impact-resistant eye and face protection, arm guards, apron, gloves, safety shoes, hearing protection, etc. Never exceed the maximum RPM marked on the flap disc!

Post time: Mar-17-2023