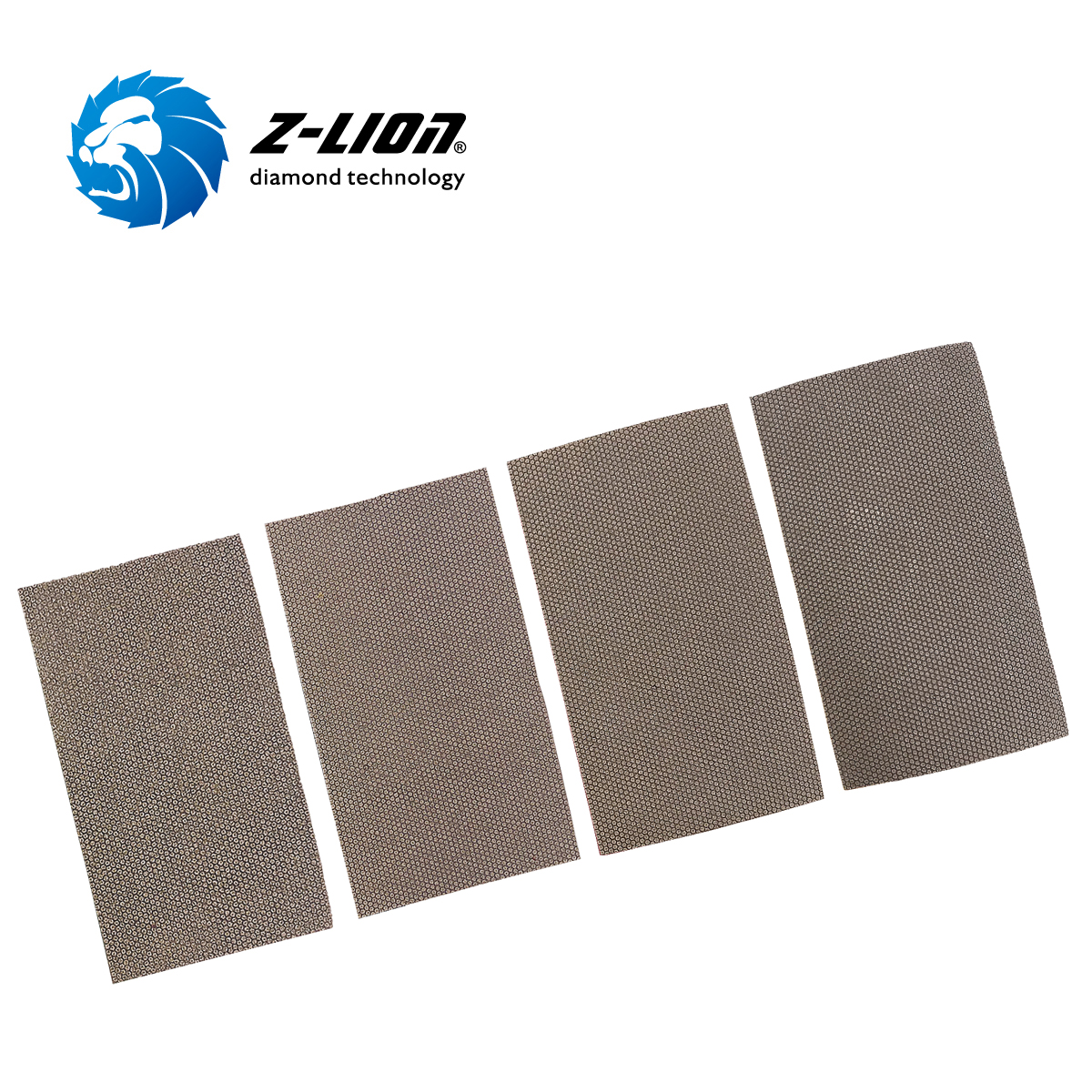

Diamond sandpaper is a cutting tool with excellent grinding and wear resistance due to its unique physical and chemical properties. Diamond is a inorganic compound substance, which is naturally produced in kimberlite. Its hardness is up to 10, and it is one of the hardest substances in the world at present. Diamond sandpaper is a mixture of diamond powder into abrasive materials for grinding and polishing materials that require high hardness and fine surface treatment.

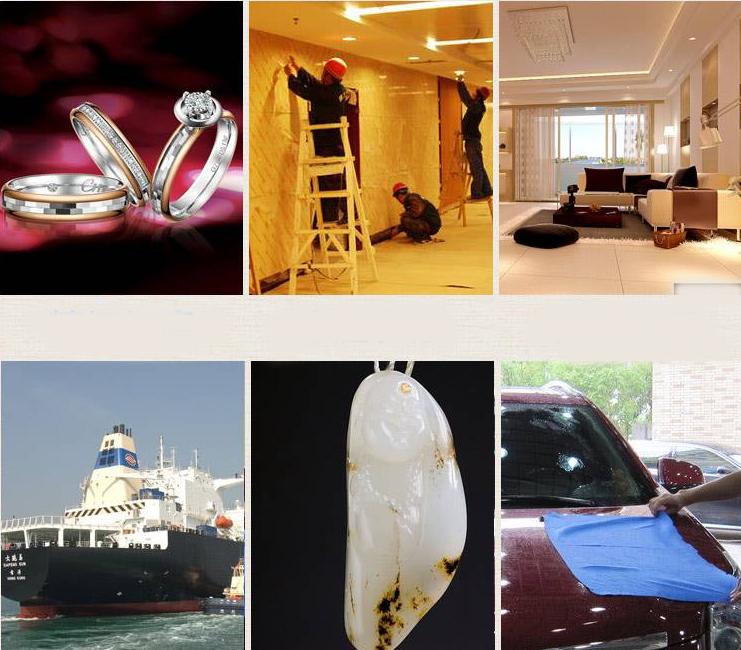

Diamond sandpaper is widely used in fields such as machinery, electronics, and jewelry. In terms of mechanical processing, diamond sanding paper is usually used for efficient grinding and polishing of workpiece surfaces, such as castings, mechanical parts, automotive engine components, etc. Diamond sandpaper can also be used for grinding various thermal spraying materials. In the electronics industry, diamond sandpaper is commonly used for polishing materials with high hardness and surface accuracy requirements, such as semiconductor chips, quartz crystals, thin film optical components, etc. In the jewelry industry, diamond sandpaper can be used for fine processing and polishing of various gemstones and high-end watch surfaces.

In addition, diamond sandpaper is widely used in fields such as the building materials industry, furniture industry, and painting industry. In the building materials industry, diamond sandpaper is commonly used for trimming and polishing hard stones such as marble, granite, and terrazzo. In the furniture industry, diamond sandpaper can be used to polish the surface of wood, eliminate defects, and make the wood surface smoother and more delicate. In the coating industry, diamond sandpaper can be used to polish coating surfaces, and due to its high wear resistance, it will not damage the grinding tool during use, thereby extending the service life of the equipment.

In short, diamond abrasive paper is a high-performance grinding material that plays an important role in modern manufacturing and processing industries. By processing various high hardness and precision materials, the surface of the workpiece becomes smoother and finer, achieving higher processing standards.

Post time: Apr-27-2023