Glass polishing requires precision and finesse to achieve a smooth, flawless surface. When considering using 3000 grit sandpaper for glass polishing, it is important to understand its properties and suitability for that specific application. In this article, we will explore the properties of 3000 grit sandpaper and its potential use in glass polishing.

Properties of 3000 grit sandpaper on glass

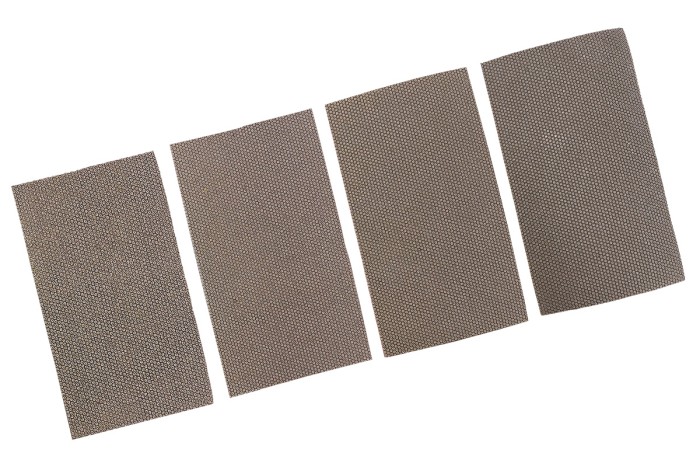

3000 grit sandpaper is extremely fine sandpaper, with grains approximately 3 microns in diameter. Its unique properties make it suitable for a variety of polishing applications, including glass. The differences between 3000 grit sandpaper and other ordinary sandpaper are as follows:

1. Effective polishing of small parts: The fine grain size of 3000 grit sandpaper enables it to effectively polish small and complex parts, suitable for fine and delicate work.

2. Smooth and fine surface finish: Due to its fine and flat properties, 3000 grit sandpaper produces a smooth and fine surface finish, ideal for achieving high levels of clarity and transparency on glass surfaces.

3. Wide range of uses: 3000 grit sandpaper is widely used and can be used to polish various materials, including metal, plastic, ceramics, glass, etc. It is a versatile choice to meet different polishing needs.

The Use of 3000 Grit Sandpaper for Glass Polishing

1. Polishing technique: When polishing glass with 3000 grit sandpaper, consistent and methodical polishing techniques must be used to ensure uniformity and avoid uneven reflection or local whitening on the glass surface.

2. Surface Inspection: Carefully inspect the glass surface before and during the polishing process to identify defects and areas that require attention. This allows targeted, precise polishing to achieve an even, flawless finish.

3. Lubrication and Control: Use a suitable lubricant or polish to promote smooth and controlled wear during polishing. Additionally, control the pressure and movement of the sandpaper to avoid uneven reflections or localized defects on the glass surface.

By following these considerations and taking a precise and careful approach, glass polishing with 3000 grit sandpaper can be effectively utilized to help repair and refine the glass surface. While 3000 grit sandpaper can achieve a fine, smooth finish, the process must be handled with care to avoid uneven reflections or localized whitening on the glass surface.

A Step-by-Step Guide to Properly Using 3,000 Grit Sandpaper for Glass Polishing

1. Surface treatment: Before using 3000 grit sandpaper for glass polishing, you must ensure that the glass surface is clean and free of dirt, oil, or other debris. Proper surface preparation is critical to achieving an even and consistent finish.

2. Moisten the sandpaper: After moistening the 3000 grit sandpaper, wipe it against the longitudinal direction of the glass with moderate force to ensure even coverage of the entire sandpaper surface. The wetting process helps reduce friction and heat generation during polishing, contributing to smoother and more controlled wear.

3. Control polishing: Increase the wiping intensity appropriately until surface defects such as scratches, stains, or oxides are effectively removed by smooth sandpaper. It is important to monitor the condition of the sandpaper and replace it with new sandpaper if accumulated bumps or irregularities are observed to ensure consistent and effective polishing.

4. Subsequent polishing steps: After using 3000 grit sandpaper to remove surface defects, it is recommended to use finer polishing compounds or materials, such as 300-600 grit sandpaper, to further refine and enhance the clarity and smoothness of the glass surface. Finally, using a polishing machine for the final polishing step can help achieve a high-quality, clear finish.

Summary and Notes

Using 3000 grit sandpaper in glass polishing requires special care and attention to detail to achieve the desired results. It is important to follow correct techniques and guidelines to avoid uneven reflections or localized whitening of the glass surface. In addition, subsequent polishing and refining processes are essential to achieve a perfectly transparent surface.

It is worth noting that if an individual is not familiar with operating techniques or requires professional-grade results, it is recommended to seek the expertise of a professional glass processing manufacturer for glass polishing. Expertise and specialized equipment ensure the highest quality and precision in glass polishing, especially for complex or high-value glass products.

By following these guidelines and considering the subsequent polishing and refining process, individuals can achieve the best results when using 3000 grit sandpaper for glass polishing, which ultimately contributes to the repair and refining of the glass surface.

Post time: Jun-14-2024