Abstract: Diamond Sandpaper is a commonly used grinding tool, used to grind the surface of the tool. It can also be used to polish metal parts, stone, jewelry and other items, but the polishing sandpaper should choose a relatively large number of fine sandpaper, so as to achieve Good polish. Generally, the mesh number of polishing sandpaper is required to be above 1200 mesh, and the commonly used polishing sandpaper is 1500-2000 mesh. When polishing with sandpaper, you should also pay attention to changing the polishing direction appropriately when replacing different types of polishing sandpaper, and pay attention to the cleaning of the polishing surface. Let’s take a look at the purpose of polishing sandpaper.

1. Can diamond sandpaper be used for polishing?

Polishing refers to the use of mechanical, chemical or electrochemical action to reduce the surface roughness of the workpiece to obtain a bright and smooth surface. Sandpaper can be used to grind the surface of the workpiece and reduce the roughness. Can sandpaper be polished?

Generally speaking, sandpaper can be used for polishing, but not coarse sandpaper and ordinary sandpaper, but polishing sandpaper with a relatively large mesh. It is a fine sandpaper specially used for polishing, which can play a good role in polishing It is suitable for polishing work of metal parts, stone, jewelry and other items.

2. The purpose of polishing sandpaper is good

When using sandpaper for polishing, it is necessary to select the appropriate sandpaper mesh, otherwise it will have a greater impact on the polishing effect. Generally, fine sandpaper with a larger mesh is required, so how many sandpapers are suitable for polishing?

The fine sandpaper usually used for polishing is generally more than 1200 mesh, and the commonly used polishing sandpaper is better to choose 1500-2000 mesh.

3. Precautions for polishing with Diamond sanding paper

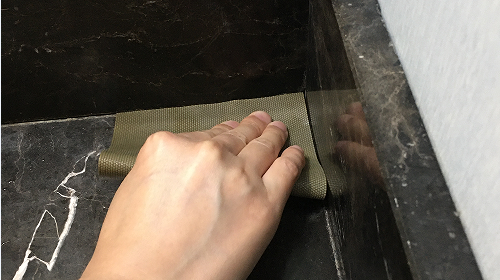

(1)Dimaond Sandpaper polishing needs to be used with soft wooden sticks or bamboo sticks. When polishing round or spherical surfaces, using cork sticks can better match the curvature of the circular and spherical surfaces; harder wooden sticks are more suitable for polishing flat surfaces. . When polishing, it is also necessary to avoid the sharp angle of the wooden strip (or bamboo strip) contacting the surface of the workpiece, so as to avoid deep scratches.

(2)When using polishing sandpaper, sometimes only one type of polishing sandpaper is not used. If you want to replace different types of sandpaper, the polishing direction of the sandpaper should be appropriately changed, and the two directions should be rotated 45°-90° each time, so that The streak shadow left by the previous type of sandpaper can be distinguished.

(3) Before changing to the polishing sandpaper model, carefully wipe the polished surface with a cleaning solution such as alcohol dipped in cotton, so as to avoid the sand and gravel remaining on the surface and affecting the subsequent polishing work.

(4)When polishing the workpiece with polishing sandpaper, pay attention to avoid scratching and burning the surface of the workpiece, especially when using polishing sandpaper with a relatively high mesh number.

Post time: Jun-09-2022