What is an angle grinder flap disc?

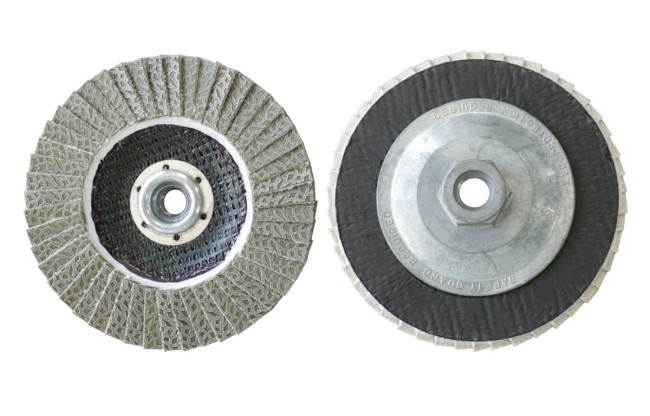

Angle grinder flap discs are versatile, efficient grinding tools that can be used in a variety of industries and applications. Flap discs have a unique scalloped or pie-shaped appearance and are composed of multiple layers of abrasive grains to provide durability and consistent performance during use. The primary purpose of an angle grinder flap disc is to grind and finish surfaces, and it is specifically designed to provide high-quality finishing on a variety of materials. The structure of the flap discs allows for progressive wear as the outer layer begins to decrease, exposing new abrasive particles on the surface. This feature enables continuous grinding without the need for frequent grinding disc changes, making it a cost-effective solution for many grinding tasks.

The composition of angle grinder flap discs, and common materials include resin, carbide, diamond, alumina, etc. These materials determine the disc’s hardness, cutting ability and heat resistance, allowing for versatility in different applications. In addition, the number and size of the flap discs can be varied to meet different usage requirements, providing flexibility for specific grinding tasks.

One of the primary uses for angle grinder flap discs is to grind surfaces on metal, stone, concrete, and other materials. This makes them essential tools in metalworking, construction, manufacturing, and other industrial applications. Flap discs effectively remove material and create a smooth surface, helping to improve the overall quality and accuracy of the workpiece. In addition to grinding, angle grinder flap wheels can also be used in polishing and mixing applications.

The purpose of the angle grinder flap disc

1. Grinding stone surface

In the production, repair, and renovation of stone surfaces, angle grinder flap discs play a vital role in surface treatment. Utilize the high-speed rotation of the louver wheel and the grinding characteristics of the louver wheel to polish, grind, and smooth the surface of the stone, ultimately achieving a seamless and polished effect. Whether shaping and refining countertops, smoothing rough edges, or repairing damaged stone structures, flap discs are valuable tools in the stone processing industry.

2. Concrete surface repair

Flap discs are also essential for repairing defects in concrete surfaces. Whether filling holes, smoothing uneven areas, or leveling defects, the abrasive action of the flap discs aids in the repair and maintenance of concrete structures. With its abrasive grit and sturdy structure, flap discs effectively address surface irregularities, ensuring the integrity and aesthetics of the concrete surface.

3. Metal grinding

In metal processing plants, flap discs are widely used for surface grinding tasks on a variety of metal materials, including sheet metal, stainless steel, rolled sheet, alloy steel, and aluminum. The abrasive properties of the flap disc remove burrs, sharp edges, and imperfections from metal surfaces, helping to improve smoothness and precision. In addition, the flap disc effectively cuts and shapes metal, making it an important tool in metal fabrication and finishing processes.

4. Wood grinding

The application of blinds extends to the wood processing industry, meeting tasks in home furnishings, architectural decoration, and carpentry projects. Whether smoothing wood surfaces, refining edges, or preparing wood for painting or finishing, flap discs improve the quality and aesthetics of wood to meet the diverse needs of woodworking applications. Its ability to achieve a smooth surface helps improve the overall visual appeal and quality of wood products.

5. Weld seam cleaning

The flap disc is used to clean and refine the weld, effectively removing welding slag and oxides to create a cleaner, smoother surface. This process not only improves the appearance of the weld but also improves the overall quality of the weld, ensuring that the joint is reliable and structurally sound. The abrasive characteristics of the flap discs help achieve precise, clean weld profiles that meet standards for a variety of welding applications.

6. Remove old coating

The high-speed rotation and grinding capabilities of the flap disc make it ideal for removing old coatings and paint layers from surfaces. Whether preparing a surface for renewal or repair, Thousand-petal Disks effectively remove surface impurities, providing a clean and smooth foundation for subsequent coatings or treatments. This process greatly helps improve the longevity and visual appeal of the surface while promoting efficient maintenance and renovation activities.

Advantages of flap discs

1. Excellent grinding results

The flap disc has high abrasive particle density and strong grinding force, which can quickly eliminate surface defects of the workpiece. As the flap disc engages the material, it provides a precise and thorough grinding action, resulting in a workpiece surface that gradually becomes smoother and more refined. This superior grinding effect not only enhances the visual appeal of the final product, it also ensures the functional integrity of the surface and meets the stringent quality standards of various industries.

2. Economical and practical

Compared to traditional grinding tools such as grinding wheels, flap discs are a cost-effective and practical solution for grinding tasks. Flap discs last longer than traditional alternatives, resulting in increased operational efficiency and cost savings. With the ability to grind multiple workpieces in less time, professionals benefit from increased productivity and reduced downtime, ultimately improving overall workflow and output. By minimizing the need for frequent replacements, the economic advantages of the flap disc are further highlighted, highlighting its value as a durable, efficient grinding tool.

3. Stable and reliable

The stability and solidity of the flap disc play a vital role in ensuring safe and smooth operation, especially at high speeds. Flap discs are equipped with a stable structure and are made of strong materials to provide consistent balance and stability during grinding activities, thereby mitigating potential safety hazards caused by grinding disc imbalance or displacement. This inherent stability instills operator confidence and promotes a safe working environment while enabling an uninterrupted and seamless grinding process. The guarantee of reliable stability enhances overall safety protocols and operational integrity in industrial and workshop environments, emphasizing the importance of the flap disc as a reliable grinding tool.

Post time: Feb-23-2024