-

What Is an Angle Grinder Flap Disc? Angle grinder flap disc is a grinding tool designed for angle grinders. It consists of multiple overlapping abrasive layers or “flaps”, usually made of aluminum oxide, zirconium oxide or ceramic, attached to a backing plate. The flaps are arranged r...Read more »

-

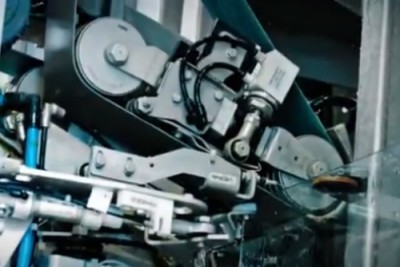

In the automotive industry, the precision and quality of glass components are crucial for safety and aesthetics. Glass edge grinding is an essential process in automotive glass production, and there are two main methods: belt edge grinding and wheel edge grinding. Among them, belt edge grinding i...Read more »

-

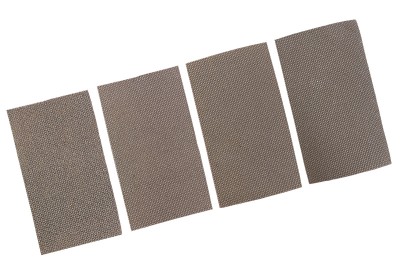

The textile emery industry plays a vital role in the textile manufacturing industry, providing essential tools and materials for fabric finishing processes. Emery is a granular rock composed of corundum and magnetite, which is widely used in the production of abrasives. In the textile industry, s...Read more »

-

Diamond sanding belts are renowned for their efficiency and durability in grinding applications. Their unique construction consisting of substrate, abrasive and binder makes them excellent at machining hard and brittle non-metallic materials as well as non-ferrous metals, such as stone, building ...Read more »

-

Ceramic tile is a popular choice for home decor because it is durable, hard-wearing, and easy to clean. However, despite its durability, ceramic tile can become damaged over time due to accidental bumps, thumps, or general wear and tear. Fortunately, repairing broken ceramic tile is often simpler...Read more »

-

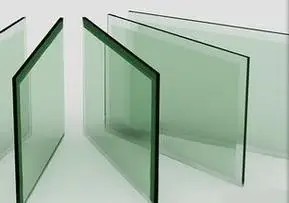

Glass is a versatile material that plays a vital role in industries ranging from construction to automotive manufacturing. Its aesthetic and functional properties make it a popular choice for windows, doors, and other applications. However, over time, scratches, stains, and other imperfections ma...Read more »

-

The Basic Principles of Sandpaper Sandpaper is designed to smooth surfaces by removing material through abrasion. The effectiveness of sandpaper depends on the size and shape of the abrasive particles attached to its surface. Grit refers to the size of these particles, measured using a standard s...Read more »

-

What Is a Flap Disc? A flap disc is a versatile tool used for sanding, grinding and polishing a variety of surfaces. It consists of a series of overlapping abrasive pieces that are attached to a backing plate. These abrasive pieces are allowed to rotate and come into contact with the workpiece, a...Read more »

-

Ceramic polishing is a delicate and essential process that enhances the beauty and functionality of ceramic surfaces. Not only do well-polished ceramic pieces look better, they are also more durable and less susceptible to stains and scratches. This article outlines the correct steps for ceramic ...Read more »

-

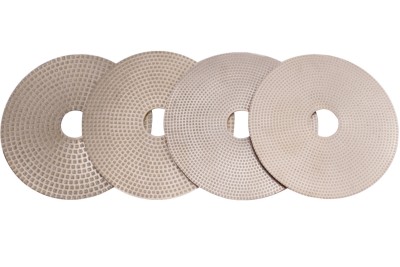

Stone polishing pads are essential tools in the stone working industry, designed for surface preparation. Their main function is to enhance the appearance and finish of the stone surface, making it look brand new. This article takes an in-depth look at what stone polishing pads do, how they work,...Read more »

-

Learn About Flap Disc The flap disc consists of multiple overlapping abrasive layers attached to a central hub. This design allows for a more flexible and controlled grinding action than conventional grinding wheels. Flanged grinding wheels are able to conform to the surface being machined, makin...Read more »

-

Glass products are everywhere in our daily lives, from glasses and mirrors to decorations and windows. However, due to improper handling or accidental collisions, the edges of glass products can become sharp, posing a risk of injury. Polishing these sharp edges is essential for safety and aesthet...Read more »